Pink7

-

Posts

638 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Posts posted by Pink7

-

-

Looks great. Congrats with your new panels and batteries.

Pink

-

1

1

-

-

16 minutes ago, lom said:

They will loosen up again, sorry to be repetitive but you are using a flat lug that will have a very limited contact surface with the switch.

It doesn't bottom out so the pressure on it will deform its side edges with time and that is when it get loose again.

Don't ask me how I know this..

Thanks for your input...I was wondering exact the same..if this just will continue. As for now the plan to get this temporary improved and working/running. Then next step I would make a plan for improved setup who also should be ready for adding more batteries in future. When I calculated and built my setup I was quite sure I would not need to expand it in the future but after experience the hot season with less optimal sun direction and school vacation with kid home and run his AC, I'm more open for the idea to expand capacity.

Pink

-

18 minutes ago, Crossy said:

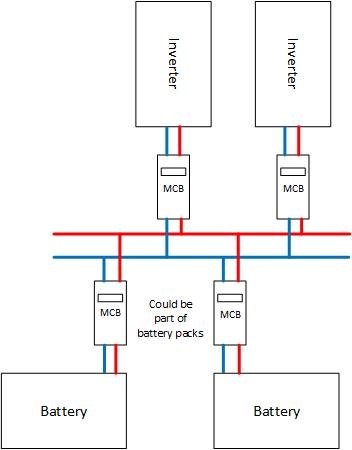

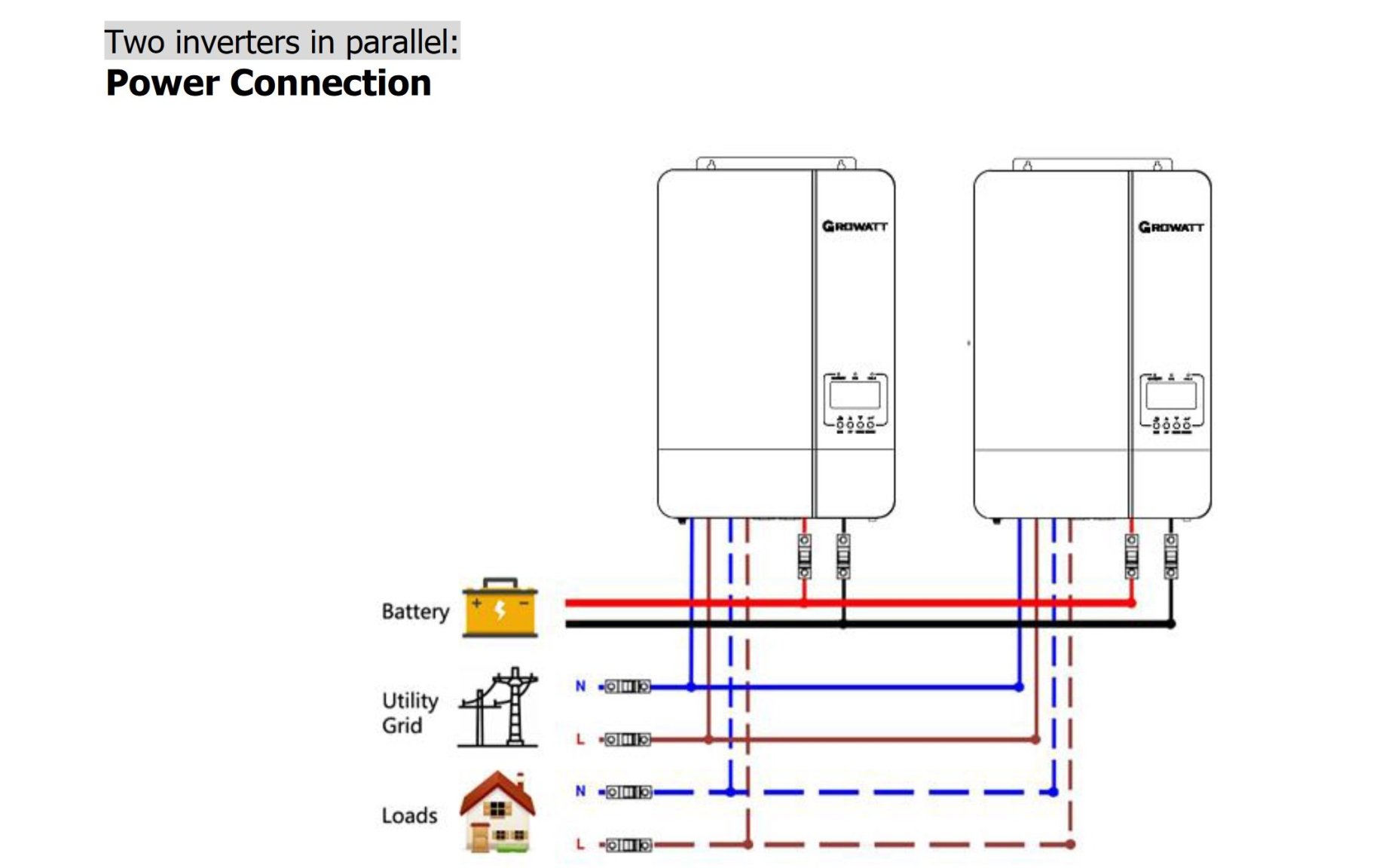

Ideally you should do something like this: -

Each inverter has a means of isolation from the batteries, each battery can be isolated from the DC bus.

How you do the paralleling is up to you of course, but as you've found multiple cables in one MCB hole is unwise.

A nice, meaty, copper bus-bar is the ideal solution.

I hesitate to post this, but I've seen this done in the past, slip some heat shrink over it, if you don't actually shrink it, you can see if the joint has been getting warm (the heat shrink will, er, shrink).

Thanks Crossy

Pink

-

Update: Temp coming down again.. after tightening the 2 screws. Learning something everyday..i will keep my eyes on this, I even consider placing 1 of 2 temp monitors from each BMS on each battery breaker.

Pink

-

Checked my battery breakers and found that the breaker i cleaned up yesterday was normal temp but the other one was very hot and so also the wire from breaker to battery. I was able to tighten the screws some and hope that will fix it.

Pink

-

Nice progress. Waiting to see more on your battery building.. Quite a upgrade you are on.

Pink

-

-

-

Correction: distance between battery wires down from the 2 inverters are 55cm. ( red to red and black to black)

Pink

-

7 minutes ago, Crossy said:

You're welcome.

Do note that it has absolutely nothing whatever to do with this afternoon's magical transformation of a 0.5mm2 BMS sense wire into a poof of acrid smoke and a slight black stain on the top of the battery pack I'm building! **

I didn't even say "Abracadabra"!

** The un-stripped end of the wire contacted the B- terminal, 4 x 560Ah (2P - 280Ah) cells in series can generate an amp or two!

I had a "almost" issue today.. I closed down the 2 bms with the pushbuttons for the bms but when i checked with voltmeter i noticed it was still power...then i see the connector to the bms for the power button had slided out so it had not power off as I expected.

There is 70-80 cm between the battery cables i want to parallel, and they are short ( inverter to breaker), so i guess i must use cable between them not just the copper bus bar. With quality thick copper battery connectors i might could connect 3 of the them on a bolt with nut? ( 1 to inverter, 1 to breaker, 1 to parallel then same in the other end of parallel cable)

Pink

-

59 minutes ago, Crossy said:

IMPORTANT NOTE: - Please don't lose sight of the fact that there is a LOT of energy tied up in your battery packs.

These packs are quite capable of pushing several thousand amps if shorted, that 1/2" drive ratchet stands no chance.

A litre of petrol/gasoline contains about 33MJ or about 10kWh => 200Ah @ 48V.

It may be "only" 48V but please treat your pack with the respect it deserves.

Thanks for the reminder. My system is up and running again now without the parallel connectors who i will find another solution for. I will fully charge my batteries before parallel them again.

Pink

-

1

1

-

-

2 minutes ago, Crossy said:

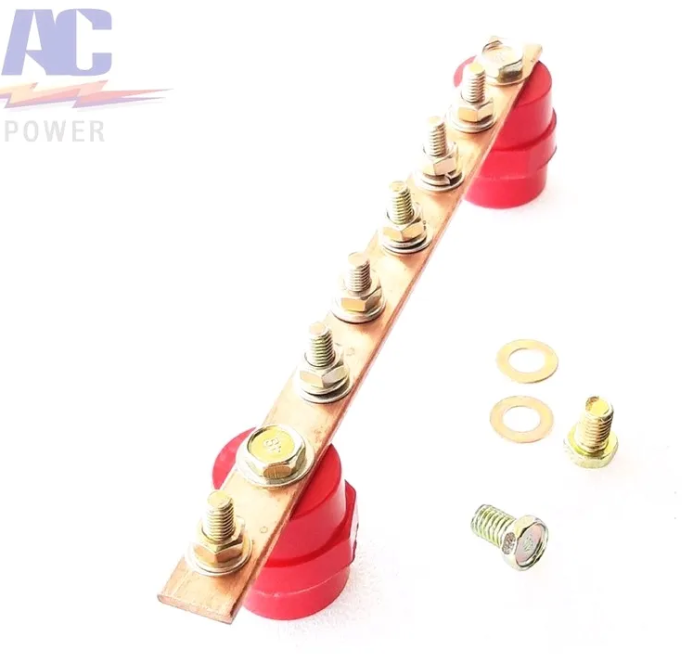

For high-current parallel connections I'd use a bus-bar with one lug per bolt.

Something like this.

https://www.lazada.co.th/products/i4750566069-s19589324451.html

Yes that could be the route to go now. Connected between breaker and inverter. Do you see any problem to run the setup some days without parallel connection between the batteries?

Pink

-

8 minutes ago, Crossy said:

I don't think I would have done it like that!!

What size is your wire? It's friend?

Lug and wire look as when it was new. Wire is 35mm2 but expand when remove the protection around and not easy to handle at all.

Pink

-

-

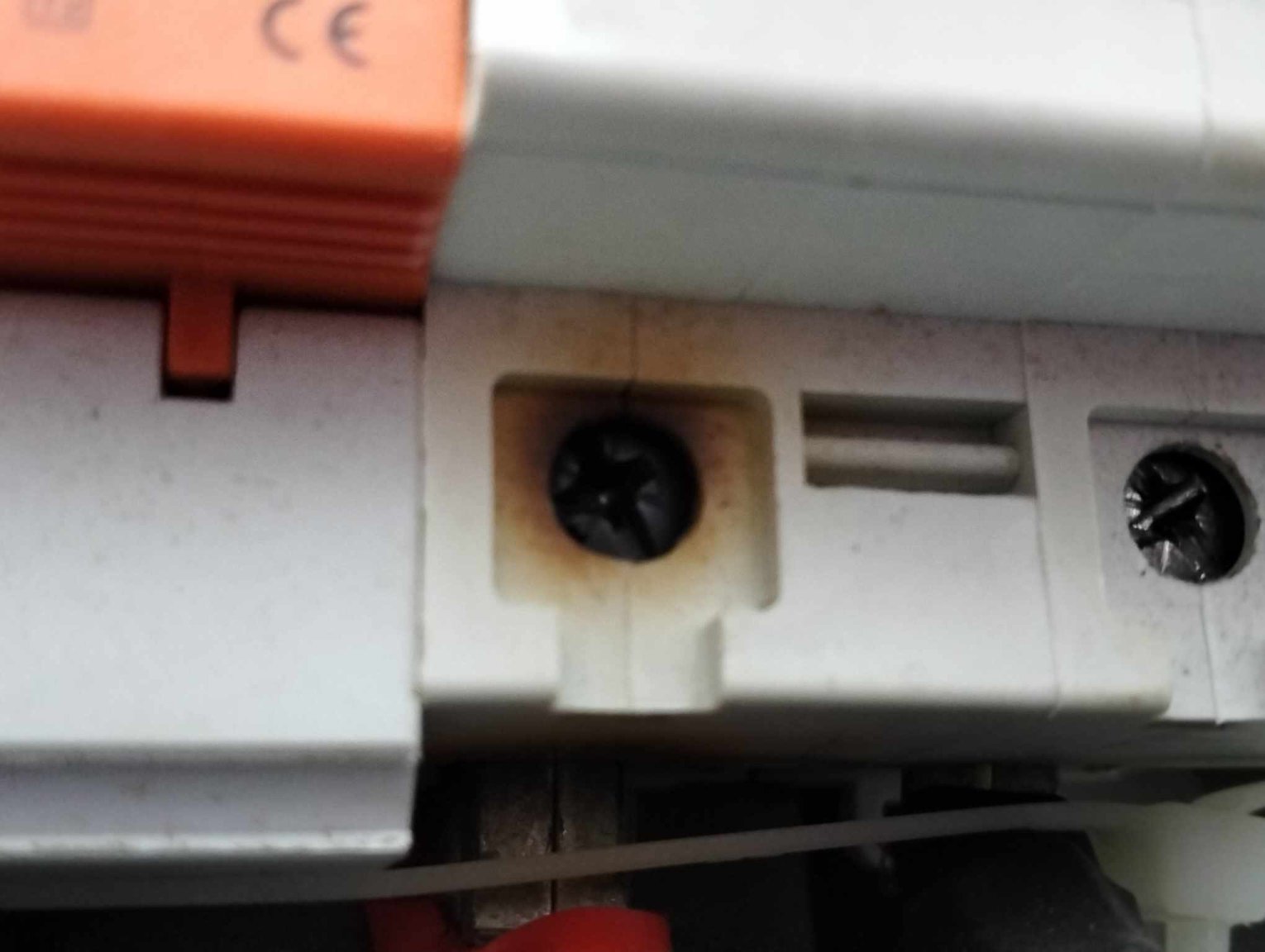

18 minutes ago, lom said:

Looks like you are using some kind of lug on the wires, maybe DZ47/C45 lugs like this:

the switch however is intended for bare wire which you can see from its rounded bottom.

I use DIN-rail enclosures for all my other switches but the battery DC switch I used is this one:

it has proper M8 hex bolts and not weak Philips type screws..

Looks good. I use a heavy duty type lug for high current. see photo

-

Currently my parallel connection is after on/off breaker and before inverter. Is there any problem to parallel the batteries before breaker on battery side?

Pink

-

3 minutes ago, Crossy said:

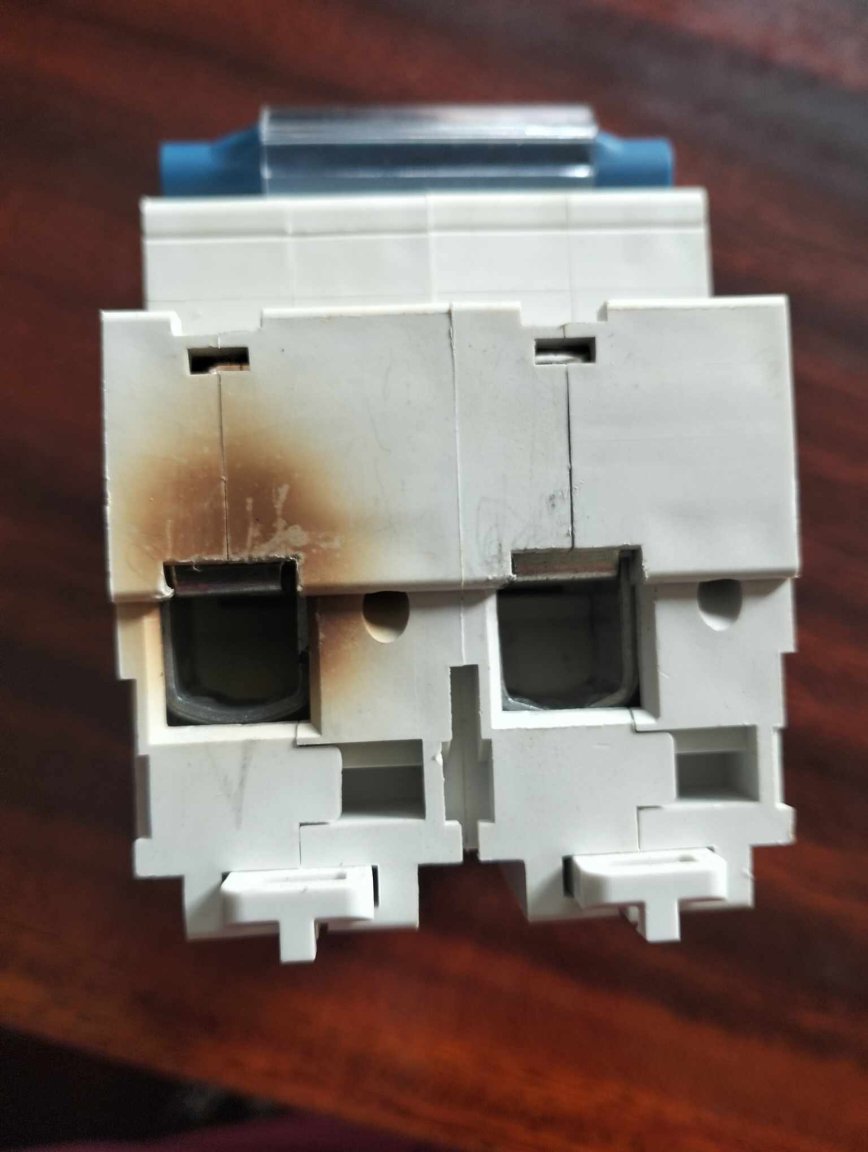

That's definitely gotten rather warm!! Clean-up and reconnect, keep an eye on it.

You may want to reconsider using two wires in one hole on a high-current connection.

Yes look so. Maybe i should dessable the wires for parallel for now. And then look for other way to parallel?

Pink

-

-

-

4 minutes ago, kwak250 said:

Now that's great.

DIY set up sounds good

What sort of price would this be?

I used THB 300K. You can see some more details here

Pink

-

1

1

-

1

1

-

-

- Popular Post

7 minutes ago, kwak250 said:Many thanks crossy for your advice.

I will check about day/night usage but will not be off grid as will need it sometimes for sure.

Maybe worth looking at doing a smaller system and no battery to start with and I can always add more later.

As we don't usually go over 25 units for around half the year a smaller system might be better but will need to see the size and consumption of a swimming pool as it would surely bring the usage back up

Was that 40-50 panel's needed as might need a bigger garage roof

Well worth the investment

my usage/production is 20-43kw per day and my 300k DIY setup is 2 x 5K inverters. 28 x 330w pannels and 30kw batteries. My electric bill used to be around 3000/month upto 4500/month, now its 38-1xx bt/month

Pink

-

1

1

-

2

2

-

49 minutes ago, Crossy said:

It's on a slow boat

tofrom China.With so good deal its worth the wait!

Pink

-

4 minutes ago, Crossy said:

How many total watt solarpanel when all up?

Pink

-

5 minutes ago, Crossy said:

Not certain yet, we certainly need an inverter upgrade looking possibly at 3 x Deye SUN-5k-SG05LP1-EU

https://www.lazada.co.th//products/i4978816678-s20977309094.html

Plus a major upgrade of the ESS arrangements.

Great inverter.

When you expect to get your battery deal delivered?

Pink

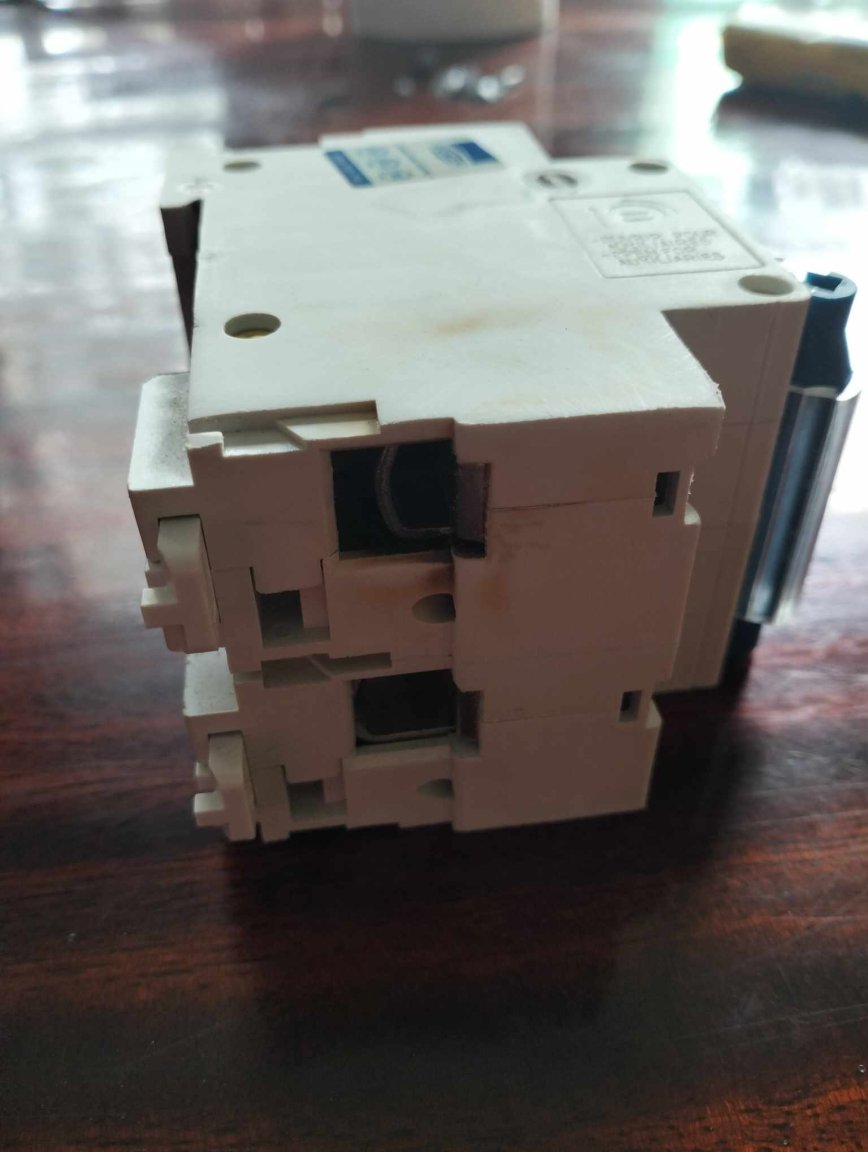

Brown spots on battery breaker

in Alternative/Renewable Energy Forum

Posted

Hello

This was taken care of asap as soon I discovered it.. Now also with temp monitor on each breaker.

Pink