TronxII

-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Posts posted by TronxII

-

-

5 hours ago, Crossy said:

It's recommended by many (but not all) in the wider battery community where you have dissimilar metals

Yeah, this "swarm intelligence" and "believes", I know, but we should always question these believes. The same goes with adding compression and charging the cells up to 3.65V just to "balance" them. Where good cells do not need more than 3.4V to be nearly full and no balancing at all. You will see, when your new cells from China arrive????

-

50 minutes ago, Crossy said:

The goop has aluminium dust which fills any microscopic gaps with a conductive material whilst the greasy carrier keeps out the damp and air.

Yes, but there where you should have copper on copper atoms touching of the two conductors, or Cu and Al (which is actually not so nice), at this point, you add another layer of something. And this something is less conductive than Cu, even if it is silver dust.

The other badly prepared parts, where no metals touch, get now some paste with a resistance of 1Ohm. Which is great, but does not add much to the correctly touching metal connection of far under 1mOhm.

So basically, adding this paste, increases your contact resistance. And 1 mOhm at 100A is 10W of loss at this point. Edit: 0.1miliOhm is 1W of loss.

Do you have equipment to measure the resistance of your connections with and without the paste? I dont have the paste, so i cannot prove my point by evidence.

-

On 12/29/2022 at 10:45 AM, Crossy said:

I would also invest in some Uni-Seal jointing compound.

Can you elaborate how you use this? I fear, you put it between the conductors which carry the high current.

Like we did in the old days with the blue stuff on car battery poles?

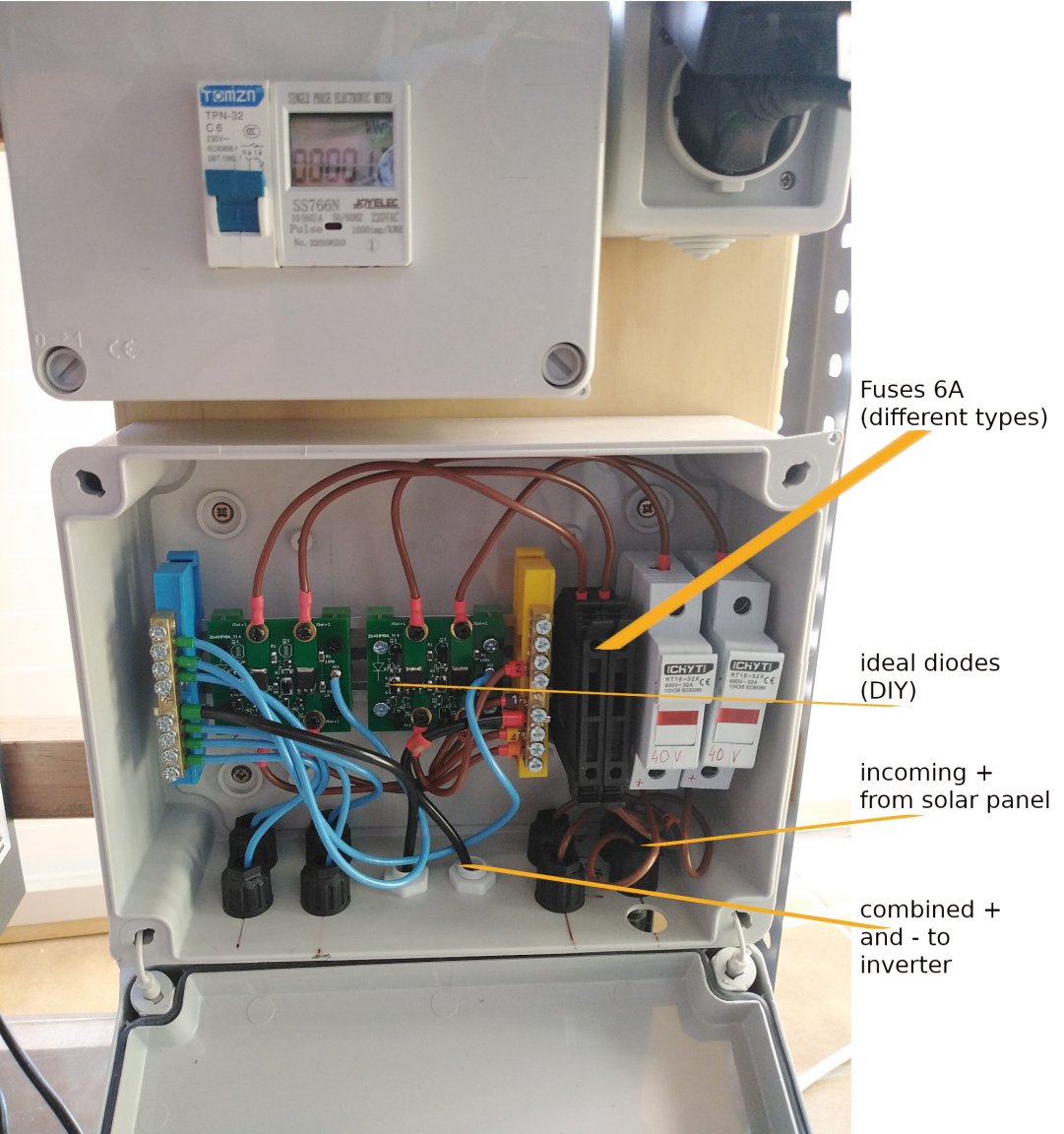

@Pink, The DIY approach is ok, but with electricity, the first failure might be the last. I would avoid voltages over 24V for my first installation, also on the solar panel side. Also these batteries are beasts, if it's your first time, I'd go with a ready made battery and not DIY.

Read about DC arcing and have a look at these pictures.

These guys explain it well.

-

-

- Popular Post

- Popular Post

Unfortunately I cannot comment on the Lazada batteries, but I've been through similar experience with the Aliexpress junk. Now with new Docan batteries, it feels like in another world, thanks to the Solar DIY forum where you are also active.

I'm planning to put a battery pack for my in laws next year.

Once you get the cells, could you please let us know how much thai customs charged or if the Alibaba seller can export them without going through customs?

-

3

3

-

13 minutes ago, Chris.B said:

their cables are 10m long which doesn't give enough length to run from the pump to the solar panel. Or am I missing something here?

Indeed, you are missing most of the relevant parts.

Power draw, Panel size, Panel voltage, can your pump start from a panel, control mechanism of the pump etc.

Find a local guy who has installed this before, or buy a kit with all components, and then come back with pictures and questions - if you have.

-

On 10/21/2022 at 6:49 PM, OneMoreFarang said:

I hope you don't expect any detailed and correct answer in this forum.

...

On 10/21/2022 at 7:19 PM, SomchaiDIY said:sometime is best to keep simple explain not all people need detail paper

Apparently @SomchaiDIY answered this question very well. If all the falangs posting here had the same knowledge as he ...

Thanks SomchaiDIY

And another thought: so these MCBs are a no go in a Panel combiner box where you parallel panels.

-

I'ts not L SC it's i SC. I is for current like U for Voltage.

SC means short circuit, this is what you measure when you connect the + and the - of the panel.

The IMP is maximum power, which is not at short circuit, but somewhere at 16V for a "12V" panel Where a 12V panel has 18 or 20V under no load. The same applies for your 24V panel, but higher voltages.

So basically, you also need to check the open circuit voltage of the panel.

I recently bought 2 new flexible 100W 12V panels, to put in parallel with my existing framed 100W 12V panels. Once they arrived, i realized that the new panels only do 18V instead of 20V open circuit. My bad of course.

This also affects the maximum power voltage and does not work well with my MPPT inverter.

-

1

1

-

-

7 hours ago, BritManToo said:

Can't tell you how much I produce as my cheap hybrid inverter doesn't tell me that information

Maybe a cheap kWh counter would make your day? These are around 10$ which is nowadays 10 pounds on Aliexpress.

I assure you that it's really cool to see the kWh going up.

The funny thing with these counter is: You can put them in any way, they will always count forward.

Some guys claimed this also for the digital PEA counters when feeding into the grid.

.png.3b3332cc2256ad0edbc2fe9404feeef0.png)

Tools For DIY Solar Projects

in Alternative/Renewable Energy Forum

Posted

Yes, and as smooth as possible, like polished, not scratched with coarse sand paper.

So add very fine grained sand paper to the list of tools.

And a milliohm meter would be on my wishlist. Then you could prove these people wrong who say the earth is round. :-), but without it's difficult...