JSon

-

Posts

9 -

Joined

-

Last visited

Content Type

Events

Forums

Downloads

Quizzes

Gallery

Blogs

Posts posted by JSon

-

-

Damn disease infested winged rats.

If someone knows a good way to exterminate them let me know.

<deleted> all over my balcony and basically live above my air conditioners. They usually fly away to the food stalls below at lunch and come back later on.

Tried the shiny reflective stuff, but they've gotten smart and realise they don't do <deleted> to them

Will look into netting, but

-

Yea, I enjoyed Seapines, very chilled course.

Caddies were ok

The free meal voucher was nice, played at 2pm finished around 5 had a nice tea supper afterwards. Big fan

-

1

1

-

-

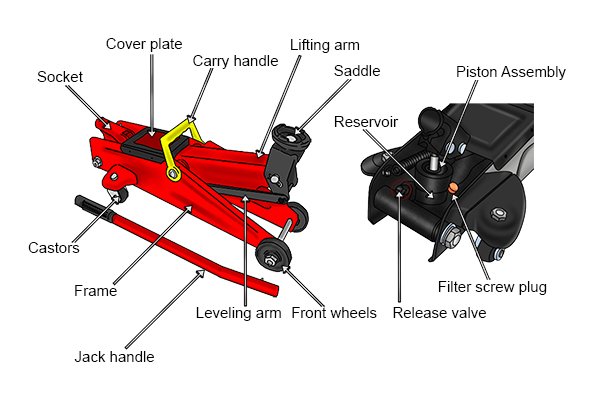

Hey, have previously been using a hydraulic jack that finally gave out after like 10 years, planning on getting a new one, the place I got it before have the standard saddle sizes but I saw that there are some with larger saddle size.

Does anyone have any experience?

I would assume a larger saddle size would reduce the pressure and therefore stress on the site whatever is being jacked, and the jack itself (probably very little here).

What are people's thoughts?

-

If I'm not wrong this is the mini one, mostly for automation, the main Metalex Event is actually in Nov this year.

https://www.bitec.co.th/event/metalex-2022

-

3 hours ago, farmerjo said:

Will check next time it's out of the box.

I don't think there is anyway to tell on the welder.

Is there a test i can do to find out.(multimeter,clamp meter)

Manual is in Thai but the jist i get is it will draw 12,500 watts at 300 amps.

I run an AVR which will show lights but not numbers.

you can get one of these clamp meters:

https://www.kovet.com/product-page/400-600a-digital-clamp-meters-ut203and use it like so:

-

1

1

-

-

On 1/16/2022 at 10:11 AM, bankruatsteve said:

I'm not likely to convert to MIG at this point. But just out of curiosity... I know the machine is more expensive but how much more are the coils (whatever) and gas? I pay B150 for 2kg 0f electrodes.

For MIG wires - you can expect between 60-80baht per Kg for your bog standard mild steel wires (replace E6013) Gas is sold usually in cylinders and how much you use is variable so harder to quantify. Usually you buy a cylinder and refill so cost is usually upfront with the tank, then refill isn't so expensive (CO2).

You can also go flux-core as many suggested, don't need gas necessarily, but much more expensive usually.

-

23 hours ago, EVENKEEL said:

Thank you for words of wisdom. You've got a good chance of being right but my experience of buying cheap doesn't always turn out well. We'll see.

Don't worry too much about it, I tend to agree, don't go too cheap, and I've definitley used v.cheap machine in the 1-2000 baht range which just failed after a few uses.

It massively depends on what you're doing though, and the thickness of the material you're using.

Need to look at what specs you need and buy accordingly.

A 120A machine isn't going to do the same job as a 250A machine and their uses are different, same with duty cycle etc

You may have overspec-ed, but as long as you weren't ripped off (the specs of the machine match the value of the machine-ish), you can always consider selling it on, there's quite a big second hand welding machine market in Thailand too, a lot of Thai's buy second hand machines.

-

1

1

-

-

5 hours ago, Adumbration said:

@BritManToois on the money here. Although there must be hundreds of pigeons at his place.

The yawata 2mm rods are the best you will get here. But you have to buy them on line because I have yet to see them sold in any shops here or in Phuket. When I was younger I worked in breakdown maintenance as a contractor in mines and quarries. Our motto was cut your way in, weld your way out. It was all stick welding back then.

My ten cents worth.

1. The cheap boxes work well however the leads are often as cheap as they get. They are also too short for a lot of jobs. You might want to invest in a better (longer) set of leads.

2. The cheap clamp on the earth lead will fail after a few months of use. Replace it with good quality magnetic clamp (shopee)

3. Although I worked as a welder for decades I moved into other work and had never even tried a auto dimming helmet. I bought a cheap one (around 360) baht and did not expect too much. It is brilliant, a game changer because you can hold materials in place with your free hand then just tack weld. You absolutely must buy one.

4. Keep your rods dry. The flux on them will absorb moisture from the air anyway because it is so humid here. If you want your rods in top condition you should also buy one of those glass bowl fan ovens. You can keep your rods in there and bake them a little (just a little) before use.

5. Avoid all of the 2.6mm Thai brand rods. Kobe especially. Rubbish the lot of them.

6. When you start out all of your welds with have slag inclusion. Clean off all pigeon <deleted> before rewelding. If you have serious inclusions grind out the old weld. You cannot successfully just weld over slag...never....

7. A little prep of your surfaces before welding goes a long way.

8. After welding you might want to mark the hot area with a piece of chalk. So you don't pick it up by mistake (good habit)

9. If possible set up your welding bench near a sink or tap, so that you can cool down items if needed.

10. If you fail and need to hire a Thai welder, never, ever, ever, ever hire one that uses sunglasses instead of a proper helmet.

PM me if you need further help.

Have you tried these ones?

Pretty much the same as Yawata in my experience, no issues, slightly cheaper as well.

Available in the smaller hardware stores on the streets in Phuket, not in HomePro or places like that though.

Agreed with some of the others - MIG is the way to go these days. Made the transition from stick a while back and it feels like going from riding a bike to riding a motorbike. MIG with either flux core/gas, flux core makes your life easier since you don't need gas, but can be a pain to use sometimes on the <deleted>tier cheap machines. Gas still produces better results in my opinion.

Got one of the cheap MIG ones like Polo on Shopee previously and it just failed after a few months of use. I had some pretty big projects as I was renovating and doing up my place so wanted a better machine went with this one https://www.lazada.co.th/products/kovet-mig-200ct-200a-dc-mig-2-talaytools-i2595738493-s9245091398.html?spm=a2o4m.searchlist.list.21.ef83631fJeIokO&search=1&fastshipping=0&sale=&price=18600.00&review=1&ratingscore=5.0&location=Bangkok&stock=1&lang=en

Been great, no issues, as good as my Forney when I had one back home. If you're going to keep the machine for a few years then it's better to spend a little more as an investment otherwise you might be throwing it down the drain.

For stick machines getting a crappy cheap one is probably ok since they don't cost that much, but if you're going to be doing a lot, I'd suggest getting a good MIG one, you won't regret it.

MRI scan - knee/hip

in Health and Medicine

Posted

Try https://www.mrithailand.com/en/

Been there myself, it was fine. Good price.

You need a doctors referral though.