JimShortz

-

Posts

1,091 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Posts posted by JimShortz

-

-

1 minute ago, GarryP said:

Thanks. Appreciated.

If your planning a house, also note the 3 high level "exhaust holes". They have Mitsubishi extractor fans on the inside and are plugged into smart plugs so that in the early hours of the morning, when the outside air is coolest, they pull in air via vents in the opposite side of the house (the low side) and blow out the hot air from the highest point of my ceilings . It is AMAZING how much cooler they make the house; for almost free - the best thing I fitted!

My roof is single plane, so those forced fan vents make a heap of sense. Having ventilation in the cement board of both the bottom and top eves also creates a natural air current between my roof and the gypsum boards - gotta love natural cooling (supplemented by AC when needed, of course!). Single plane roofs may not be beautiful, but they sure are practical! -

-

4 minutes ago, GarryP said:

Could you post a pic of the concrete board with mosquito proof ventilation holes you used. I had not heard of them before. I am in the planning phase for my new house and trying to get as much info as possible before plans are drawn up. Actual build will start in a few years.

I don't have a better pic to hand, but you can just about see it at the far left of the picture. On the hidden side it has what is effectively strong mossie screen "tape" stuck over the rows of holes (it appears to be epoxyed in place). Not many places in Chiag Mai have it, but I know Global House now stocks it. I wanted it to keep the geckos out of my roof space!

-

1

1

-

-

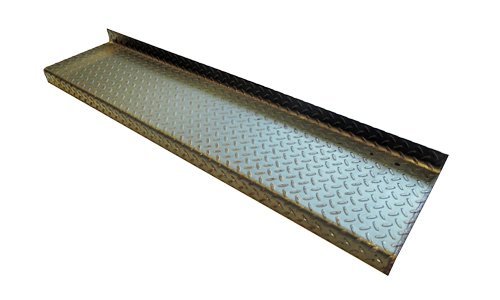

Yes, I agree, not wood! The guys who installed my gypsum board (inside), and concrete board with mosquito proof ventilation holes (outside, under the eaves) installed a layer of light metal galvanised strips that are then screwed into directly through the board with no need for drilling. Mine are at 40cm centres to prevent sagging (at their recommendation), but 60cm centres is basically fine too - or so they told me.

Like this (and it is cheap as chips):-

2

2

-

-

43 minutes ago, transam said:

I just bought an LG 9200BTU from Dohome where I live, a new model with twin inverters, which they say makes it cheaper to run, for 12,900bht, which included installation, which was free.

I was replacing a 12 year old Daikin 9,000BTU because they tried everything to get it blowing cold and was told "can't fix"...Hmmmmm....

Anyhoo, the LG is great...Google it for a read..LG IG1ORN.SE2..

That certainly looks like a very interesting offer, with a SEER rating of 18 and a very cheap price! LG apparently make pretty decent ACs too?

-

34 minutes ago, tpthai2 said:

Try this guy. Excellent English and work ethic.

Air Con

Charley

082-766-0426

Thank you. Does he sell AC, or just an installer?

...and thank you to everyone else for very useful input. I'm still unsure which way to go, being unconvinced that the higher SEER will in reality make sense vs the cheaper one - but I guess not a vast difference either way. Still thinking... ???? -

- Popular Post

- Popular Post

1 hour ago, cheeryble said:If not if I was you I would go for the regular metal sheet from top to bottom one piece Probably cheaper too .....And certainly nice to have that glued on thin insulation I don’t think you need to think of expensive stuff that’s profiled, Combined with Rockwool on the ceilings rock wool on the ceilings it’s great.

Your sheets will most likely involve wastage two as your Sheets are unlikely to fit exactly top to bottom where as the long metal sheets Are just cut to length

I certainly agree that single lengths is great to ensure a leak free roof, even in the fiercest storms. My lengths were 9.1m and almost unbelievably they came on a pickup with a special frame fitted (see picture earlier in the thread). I also agree that the 2 or 3mm glued on insulation with reflective foil massively cuts down heat transfer and deadens the sound of rain. I fitted it on my outdoor bathroom that I built ahead of building the main house and I am very happy with it. Mine's been on for a year and hasn't sagged or fallen apart yet, but I have seen many that have. I don't know how you go about choosing the good stuff? I guess I was just lucky. I bought that from Lion Steel in Hangdong, Chiang Mai. I'm glad to hear yours is working out well for you.

I also want to share in more detail, for anyone interested, the alternative way I chose for my main house:

For my main house I chose the "hard" bonded insulation from Bluescope and am super pleased with it. I also went for the foil bonded on its underside to prevent heat radiating downwards, but if you were leaving it exposed there is a paintable option too. The bonded insulation actually gives a flat ceiling to its underside and I have seen a friend leave this exposed on a "lean to" to his house and painted it to match the house - it actually gives a decent flat ceiling and looks good.

The real reasons I went with the 25mm bonded insulation is that it is much quieter during rain and very little heat passes through (25mm insulation makes a significant difference compared to a couple of mm). I have a gypsum ceiling fitted 8" below the roof (at the same angle) with no rockwool and have mosquito proof ventilation all the way along both the top and bottom eves.

The idea is that air enters at the bottom eve, passes between the gypsum and the well insulated roof covering, and any heat and moisture that is there leaves at the top eve. I have to say that it works really well - physics in action I guess! The idea behind no rockwool being installed is partly to save money on something not needed with this system, and also to let heat out through the gypsum at night. It seems that with the well insulated covering and good "attic space" ventilation the rockwool isn't needed - at least on my house (my gypsum ceilings are just at ambient temperature, even in the middle of the day). I also went for a white colour on top since the way my house is situated you never see the roof anyway, and it is by far the most reflective colour - again keeping the heat out of my tiny attic space!

My covering with the 25mm bonded insulation cost B100,000 including fixings for a roof of 26m x 9.1m (237 square metres). That works out at about B420 per square meter for covering (including fixings and flashings) with no loft insulation to buy. Not super cheap, but not bad either and is certainly one way to a quiet, cool, and cost effective roof. YMMV! ????

-

2

2

-

1

1

-

I am beginning to think the lower priced unit may indeed make more sense, especially if I can get reasonable priced installation. I don't suppose you are in Chiang Mai and can direct me to better value installation?

Anyone got recommendations for good quality good price installation in Chiang Mai? Thank you ???? -

I have three small bedrooms (around 12 square metres each) to buy ACs for. I have pretty much decided to buy Daikin for their excellent reputation, unless someone wants to convince me otherwise?

My two Daikin Inverter options being considered are:- FTKQ09SV2S for B10,560 with a SEER value of 16.66

- FTKC09RV2S for B15,990 with a SEER value of 20

Clearly the second one is cheaper to run with the higher SEER value, but by how much? I am partly confused because the second one has a "magic eye" function that allows the room temperature to raise a little if it senses nobody in the room. I'm guessing that this feeds into the higher SEER value, BUT since these are bedrooms and will contain people if the AC is on then this is essentially irrelevant. I guess what I am asking is does anybody understand how SEER values are calculated, and is it likely that for me the real world SEER values may be actually much closer together.

Does anyone have any thoughts on these ACs? Or alternative AC suggestions (high SEER and good value!)

I am pretty much sold on the more expensive of the two. I am in Chiang Mai and was thinking about ordering from these guys, at B18,900 including installation, piping, brackets, etc. Is that a good deal? Anywhere else in Chiang Mai I should be asking? (I want a local company so that I have somewhere to go if there are problems). -

- Popular Post

- Popular Post

I should've mentioned that the Bluescope steel roofing came from the place found at (18.761777, 99.041102). It doesn't seem to come up in any English search, but this is the main Bluescope place in Chiang Mai and the prices via them are comparable to non-Bluescope elsewhere. You will, of course, need a Thai speaker. We found their service and prices to be excellent, and with a large product range too.

If you buy Bluescope from anywhere else it is much more expensive. I don't know for sure, but I assume all of the other outlets are just resellers from this place - with associated price mark-up.

You're welcome... ????

-

2

2

-

1

1

-

- Popular Post

- Popular Post

I just had a single plane roof completed on a new build house. For an idea of costs, my roof at 26m x 9m was:

Covering: Bluescope colorbond galvanised steel, with white colour bonded on top and 25mm of bonded insulation underneath, cost just about exactly 100k Baht including delivery, flashing and and all fixings, but not including the actual installation (that was done by the people who constructed my steel roof frame as part of the price for the whole job).Roof structure: all done with high quality steel box section at 2.6mm thickness, except battens at 2mm. The whole building area 26m x 7m had a 4" square ringbeam and the same beam down the centre of the building. The 3" x 1.5" rafters are them placed at 1.5m centres and 2" square battens on top at 1m centres. Rest assured that this is a super strong structure if done with good spec steel, and no cheap C sections. Painting, welding (excellent seam welding all "linear" joints in ringbeams, rafters and battens), installation of the Bluescope covering and flashings, and installation of fake wood fascia boards, by a really good team of three welders cost me B60k Baht in labour + about the same again for steel.

Total roof cost about 220k Baht - an absolute bargain for a very strong and highly insulated and reflective roof! And it's not noisy or hot at all either; the bonded insulation is fantastic.

PS, I originally planned it with 1m centres for the rafters and it was the main man at Lion Steel who said for this structure (only 3.5m between each ringbeam that the rafters cross) that was excessive. He said I could go as far at 2m, using quality steel of decent thickness, but I compromised at 1.5m and am super happy with the decision.

I also think I got great welding because the guys could seam weld the decent thickness steel (I weld fairly well myself, and thin steel is a bitch, it just melts away, leaving holes). I also bought them 10kg of good rods so that they wouldn't be shy with them!

-

3

3

-

1

1

-

15 hours ago, sometimewoodworker said:

Your points are interesting but totally off regarding needing thicker render for AAC, having looked at your walls they are certainly less smooth than any AAC walls I've seen, they would certainly need a a greater depth of render that mine or another's I've seen.

That clearly demonstrates that your plasterers did not do a good job, didn't know their job, or that the material was substandard.

Jeez... no wonder so few people want to come near Thaivisa anymore! It has become the butt of jokes about grumpy old men on many Facebook groups... After this post I give up trying to share my experiences and opinions, because apparently I am wrong all of the time! This is my last effort to try and help you understand what I am sharing. If I wanted constant correction I would go and see a strict mistress, not post on Thaivisa! ???? My apologies if that is rude, just feeling very frustrated right now!

Just to clarify for you, once more, as simply as I am able... I don't think that AAC per se, needs thicker render (I know they don't - it is common knowledge!), BUT, if you are using village builders (as I clearly am from what I wrote), with associated minor inacuracies in posts, lintels and/or blocks then a thicker render would be desireable for a high quality finish, hence NOT using AAC (my walls are NOT AAC, hence being "less smooth than any AAC walls I've seen" - no shock there!). This is what I did, and why I did it. Is that okay with you?

The plastering deal is much the same. Note the part about village builders... this is the key to understanding. The final finish they produced was excellent barring some surface roughness. Yes, they could have polished it, had I asked (and they did on selected areas that I won't paint, BUT, this is how I chose to do it). It is not wrong, just not the same as you chose. My overall finish is excellent, as I am sure yours is, and my builders are good local men, known to my family for a long time, who have become "friends" - and they won't be having me shot!

Two ways to a different end! Just maybe, some other people don't have "master builders" and "superior materials". They may like to see an alternative way - working with competent village builders, using materials they understand and are good with (albeit with a slightly different block, but one that can be used with traditional mortar and render), to reach a very acceptable end product.

AAC and master builders are not the only way... In fact, my stronger walls and ease of fixings is a major boon for me. As I stated in an earlier post I do have an AAC building (4m "cube" workshop). For both the strength and the fixings I wish I had built that with LCBs too - JUST MY OPINION THOUGH. Others can make their own judgement; if we are allowed to share information/opinions in peace!

Bye, bye, Thaivisa... so long, and enjoy the grump! ????

-

1

1

-

-

aah... I though I had explained. My apologies if this is still unclear for anyone. I'll try again, as clearly as I can:

If thicker render is needed to deal with posts, lintels, village building, etc. then the cost of bagged plaster for AAC blocks mounts up rapidly versus a sand and cement based render as used on my Lightweight Concrete Blocks (large (same size as AAC), aerated cement blocks, not cinder).

Labour costs for me were low, using "village builders", but thicker render was needed. The overall finish obtained this way has been excellent and I love the stronger walls and ease of adding fixings (I just shelved out a full height 3 sided pantry with regular plugs - strong and simple). AAC is a perfectly viable alternative, and can work great - I'm just sharing my experience of how I got what I am happy with, at a price that worked out great for me. YMMV.

I don't know about special "render quality" sand, but the sand that was used was bought for that purpose at a reasonable price. Once dried out, all walls were then lightly sanded with a 40 grit sandpaper to remove any sharp surface grains of sand (by me and my family - no cost, if you ignore listening to moaning teenagers! ???? ), before filling of any minor imperfections, application of the raw concrete primer and then two top coats of quality acrylic paint. The overall finish is excellent - just the stipples of a rollered finish, no indication of sharp sand or imperfections.

My intention was to help others see alternatives to AAC, since this isn't much talked about elsewhere. Have a nice day. I hope you are all equally happy with your choices ????-

1

1

-

-

23 hours ago, sometimewoodworker said:

No saving at all as the AAC render is cheaper than the render for cinder blocks.

Just to be clear, I haven't been using the cheap cinder blocks with the holes down the middle. The solid Lightweight Concrete Blocks I have used are in many ways like AAC blocks, but not autoclaved. They are the same dimensions and degree of dimensional accuracy, have similar thermal and sound insulation properties (something like 15% less good, but still excellent). They are also are slightly heavier (more dense), absorb water less readily since the "bubbles" are closed, and they can take regular render (again, due to their more "closed cell" makeup. They are not widely available, but can be found, as I described in another post.

-

2 hours ago, canopy said:

Also remember AAC mortar comes out cheaper because it is laid thin and the blocks are longer and taller. That also means speed which saves labor cost and improves build time. But you have to look at the whole picture. A builder told me AAC, breeze blocks, or red bricks really has no effect on the final cost of a house. It just comes down to personal preference.

I love the qualities of AAC render. It can be easily sanded smooth or into bull nose corners. With AAC you do need to use approved fasteners for furnishings and results will be as good as any other.

I very much agree, in theory, and have a 4m "cube" workshop with Sala on top built from AAC. I guess it depends how you are building, and who your builders are, but the "thin" part works not so well where there are cast concrete lintels, strengthening beams, etc. and the result for me was less "sharp/precise" rendering than is commonly achieved with sand and cement render. I'm pleaseed that I built this before the house. It was a good learning experience for me.

I am super pleased with the sand and cement rendering that I have on the 60x20x7.5 LCBs (same size and dimensional accuracy as AAC blocks) on my main house. This type of rendering is something that Thai builders are often familiar with and very good at, and the strength it gives to otherwise quite weak walls is a real advantage imho (especially on the interior walls which are single skin in my case). I know that if you use the AAC blocks with precise laying, the proper AAC lintels, etc. and have the right builders, a single 5mm skim of AAC render is possible - it's just not what happened for me.

Both options can work well. I'm pleased the AAC worked well for you. The LCBs have worked out much better for me. Each to their own, I guess, I just wanted to share what had worked well for me. The LCBs are a great choice for people with "village builders" - it isn't too much of a stretch for them, and a great improvement in thermal insulation over the other regular "Thai" block/brick options ????

-

By the bag maybe, but given that it isn't mixed with sand, but just mixedd with water like a western plaster, regular sand and cement render is much cheaper. It also allows for Thai style thick render and associated strong surface for fixings. It has worked out great for me...

-

Actually, on checking, it seems my blocks were 7.5cm wide.

For anyone interested to know more, we bought SLP blocks directly from the factory where they are made (we went and saw this happening - very cool, at least for me!). If you are interested, Google SLP Chiang Mai you will find some Facebook links to get you on the right track ???? There are several manufacturers in Chiang Mai but I found zero information about them in English - my wife tracked them pown for us in Thai.-

1

1

-

-

I used solid (no holes) Lightweight Concrete Blocks in place of AAC because you can use regular render on them, and this is a massive saving, especially where thick render is required to deal with posts, etc - and it allows Thai builders to work the way they know, albeit having to wet the bricks before laying, and again before rendering. I also like the hard concrete render coat as it makes wall fixings a breeze. These LCBs are available from several companies in Chiang Mai and I paid B17 per block (20x60x7). They have something like 85% of the thermal efficiency of AAC without the special render drawback.

To deal with the wall tie issue I had my walls set out to total 20cm width then had every 2 or 3 courses laid on their side. This creates a good thermally efficient wall that is tied together, is strong, has closed cavities, and works just great for me - and no metal ties to rust out!-

1

1

-

-

Amorn has the small sets for not very much - several branches across the city

-

Lots of good advice here, but there is a big case of "how far do you need to go?". Do you plan to live forever?

My advice is to not try to be too different to what your workers are used to, but insist on decent wall thickness steel. So, my tuppenth is to:

- listen to the guy about warping (box section is surprisingly easily warped by stick welding - has caused me many headaches)

- Buy steel of wall thickness 2.3mm (perhaps 2.0mm for battens), not the common 1.6mm that many use. The thin stuff is a pig to weld and you get holes easily; also rusts away easily.

- Unless it is very oily just paint with red oxide before welding, then at welds afterwards. For very oily steel you may need to wipe first, but it does just mix fine with the red oxide; save your effort for something meaningful!

- put a roof on top, box it underneath and leave for many, many years - decent thickness steel, in the dry, lasts for many decades this way. Why do more? Go with the flow...

I understand about multi-layered paint, clean surfaces, seam welding, etc, but it is not a ship, and the above will outlast anyone old enough to be reading this on Thaivisa, and quite probably their chiildren too! ????

-

Here is a document I made using terms from a variety of sources, including that linked to above. It is intended to be printed back to back - so that you can use them as flashcards to learn. I never finished it, but there is a lot of key vocabulary here anyway.

You're welcome ????-

1

1

-

-

For the north of Thailand you can find detailed routes (created with Kurviger) provided in the Chiang Mai Motorcycle riders Facebook group:

-

Thamk you Eyecatcher. Not far from me too. Much appreciated ????

-

.png.3b3332cc2256ad0edbc2fe9404feeef0.png)

Total price per square meter for a metal roof made with metal roof tiles with insulation underneath?

in DIY Forum

Posted

Yes, exactly that - nice and simple. You can buy those strips from Global House, or any of the other big building suppliers.