-

Posts

1,294 -

Joined

-

Last visited

Content Type

Events

Forums

Downloads

Quizzes

Gallery

Blogs

Everything posted by Encid

-

Good idea... I'll pass it on.

-

Yesterday the additional raw water tanks were placed on the concrete base and piped together with a common 2" suction header to the 250W pump. The pump will provide water to a 2" ring main around the pond and also a 2" feed line underground across the plot to the concrete slat wall and then to the Guest House. Various 1/2" offtakes will be located for gardening/watering purposes along the route. The suction header will also act as a common fill line for all 5 tanks so the level inside the tanks will be the same. The fill line comes from our PV solar panel powered submersible pump in a bore/well. All 5 tanks will have an overflow line each which will discharge to the pond when the tanks are full. It will initially be a manually operated system, but I hope to automate it one day with a float switch and a relay to the sub pump which is about 200m away. (If anyone has some ideas on how I could do this I would much appreciate it.) I do not want to have a repeat of the problem I saw just a few weeks ago... Our single tank had run out of water and FIL had turned on the solar powered pump to fill it, then he headed off to burn some wood in another part of the farm to make charcoal. BIL had stayed by the pond and was supposed to turn off the pump when the tank was full. He forgot and was just watching the water jet out the overflow without a concern in the world. He was sitting in the shade at the other end of the pond so would not have had a clear view of what was actually going on. I happened to walk past at the time and noticed that the overflow was gushing out of the tank and that the energy of that water exiting was enough to push the tank backwards off it's base. It is a 2" supply line but only a 1" overflow line. I yelled at him to turn off the pump before any damage occurred. After he returned and the tank had settled back down onto it's base I showed him the photo and he was genuinely shocked. We inspected the fill piping for any damage but none was visible so we were lucky that the LDPE line was flexible enough to take the bending without breaking. Lesson learned and that is why all 5 raw water storage tanks are going to be piped together... so that they all fill (and get emptied) at the same time, and that they all will have overflow lines so the situation above cannot happen again.

-

Thank you Hopefully that won't happen with our build. The under-roof area (or attic if you like) steel should not be subjected to wide ranging temperatures as we will be using 50mm thk PU foam-backed Bluescope steel for the roof, and the ceiling will be covered in 150mm thk SCG "Stay Cool" insulation, so the actual steelwork will not see any direct heat from the sun nor radiant heat from the roof steel. If the steelwork does creak a bit hopefully the insulation will deaden the sound somewhat.

-

I know what you mean... I have seen many houses built by local "builders" who do not work to approved architect's plans and just construct something to a budget, not to a design. And most Isaan village houses are not "approved" by any government agency either. We searched for a builder within a 120km radius who had a proven track record, built quality houses, and took pride in his work... and could also work to a budget. We were not going to use the local "builders". We were lucky to find one based in Khon Kaen and happy that he agreed to undertake our project.

-

Our builder has a couple of qualified structural engineers on his staff (I have seen their qualifications) and he runs things like this past them to determine the actual sizing, but I think that he (like so many other experienced people) can offer a qualified opinion based on his experience of building many houses. Same as me when I saw the mesh that was originally placed for the raw water concrete slab... it just looked wrong.

-

Today the mesh for the raw water storage slab was replaced by RB12 rods, and the roof frame partially assembled: This afternoon the concrete was poured: And the additional 2000L tanks and the 2" PVC pipe has been delivered.

-

Now... our second change to design... removal of one column. When we were walking around the build and getting a feel for the internal dimensions of the GH, both my wife and I agreed that if possible, we would remove one column as it took up too much space in the open living area. (They are all 20 x 20cm in size.) It was a "hangover" from the original architect's design when we had a flat concrete roof, and this column was needed to provide structural support for the heavy mass of reinforced concrete. But when we changed the roof design to a sloping steel roof behind a rendered AAC block façade, we didn't change the size of the columns, just the amount of reinforcing steel inside them. This is the column that we wanted removed: We discussed this with our builder and asked him what it would take and cost to remove this column. He answered that the roof steel (which he was just about to order) would need to go up one size as it would be spanning 6m instead of 4m and it was no big deal. We asked about cost and he said about 3000 baht plus the labour to demolish the column, to which we readily agreed. He then informed us that he wanted to change the plan due to 1) the hot weather, and 2) some of the workers did not want to go home for holidays at Songkran... they wanted to work through, so the next step would not be the erection of the AAC walls but the installation of the roof so the workers could have some shade. No problem for me… I’m sure that they will be happier and not take (so many) shortcuts if they are working in more comfortable conditions. I still bring my laser level with me every time that we visit…

-

Is 100% Thai... believe me! He is very agreeable by nature (as another forum member who had his house built by the same builder has attested) and does not get ruffled at all. He (like me) is not on site very day and relies on the the photographs that his foreman sends him. The reinforcing mesh in the slab for the raw water tanks was placed by his foreman, and our builder had not seen it, so he agreed with me. He knows that my wife's family also send me daily photos so I can see the progress and hopefully catch any problems before it's too late. He knows that I am not a trouble-maker, but I do want a quality job and I am sure that he will try to deliver. He does pride himself on his reputation and wants to keep his customers happy.

-

I contacted the builder last night and showed him this photo. I told him that I didn't think that the steel mesh looked strong enough to adequately support the additional raw water storage tanks. He said he would look into it. This morning I received a message from him as follows: "I'm sorry, I was wrong to give less importance to this than the house, today will tie more steel and add more concrete". I really like this builder.

-

It is a 3D spatial limit, not a height limit. In that particular area we want to fit our water pump, our water filters (particulate, activated charcoal, and ion exchange resin + saline regen bath, plus a washing machine and enough spare area for hand-washing, as well as the tank(s), and the footprint for all that gear is fairly tight... the only constraint in the vertical plane is the roof and it's supportive beams. Short fat tanks are not being considered due to footprint constraints.

-

And as of this morning (5 March) the raw water storage area has been cleared by hand and boxed in (using surplus concrete panels from our panel wall) and is ready for reinforcing mesh and concrete. The slab extension for the counter is also ready to receive concrete. And the slab extension for the filtered water storage has been boxed in and is ready to receive concrete. The location has been agreed for a floor drain (to be installed before the concrete pour) and soakwell to service the washing machine outlet.

-

We also asked for some concrete steps to be built so we can step down from the filled land level to the pond level in comfort and safety. It was hot and dusty work and the soil is very hard due to the heavy rains over the past 12 months compacting the land.

-

The next day the preparations for the extra work and the remedial work to the GH started... holes drilled into the slab and starter bars inserted for the slab extension, boxing prepared for the counter extension, and precast concrete columns erected to form the supports for the water tank storage area at the pond.

-

At minimum a 2000L tank, but maybe more than that depending on head room. My builder has not yet told me what sized steel beams he will be using to support the sloping Bluescope steel PU foam roof raked at 15° for future PV panel installation. (Remember that our original architect's design was for flat (slightly sloping) concrete roofs at various levels, but our builder managed to save us 20% of the build price by using less steel in the concrete beams and columns to support a sloping steel roof behind a rendered AAC block façade). I have used CAD to set out some working dimensions and have calculated that if he uses a 60cm deep beam I will have enough room for 2 x 2000L tanks plus our filters, pumps, washing machine etc. If his beam size is not as deep, then we might be able to increase storage tanks size to 2500L or 3000L, but with the additional raw water storage tanks over at the pond we do not have to worry so much about filtered water storage at the GH.

-

The extra work that we wanted him to do was to add some additional water storage at the pond because the 2000L tank was running dry every day. Yes it was filled every morning around 10am when the sun was high enough to activate the PV panels that drive the solar powered bore pump, but the amount of water his teams were using for the build as well as their own personal usage resulted in the tanks running dry in the early afternoon, so someone had to go over to the panels and start the pump again... but that doesn't work if you have thundery clouds floating around. So the existing tank and pump sits at the West end of the pond (which FIL has been draining and catching all the fish before the workers can claim them): We will add an additional 4 water storage tanks and erect a cover over the top of them all to keep the sun off them, and that will give us 10,000L of storage. The piping from the 250W pump will be increased to 2" diameter and be run around the pond as a ring main in a trench so it can be covered and protected from the sun, with 1/2" offtakes to hose stations around the pond (for gardening purposes) and another 1/2 offtake to the toilet at the East end of the pond. The 2" pipe will then be run underground Eastwards over the site until it reaches the retaining wall, then run up the side of the retaining wall until it reaches the Guest House. This pipe will be the water feed (after filtration) to the tank(s) in the carport which in turn will be pumped into the Guest House for household usage. We will probably use a float switch in the tank(s) to ensure that they are always full. We have no plans to filter our bore water to safe drinkable levels yet, as there is a local water factory about 5km away that supplies and delivers 20L bottles of drinking water for 20 baht each in our area. Maybe a future project?

-

We did notice a couple of errors and that the people on site were not working to the latest drawings. We had a meeting with our builder the following day so we could discuss rectification of the errors before it was too late, and also to discuss some additional work that we wanted done. The problem areas were as follows: Firstly the concrete base for the deck/Thai kitchen needed to be extended by 20cm to cater for a counter, and the carport slab needed to be extended as our water tank(s) were going to sit on the RC beam that spans the two columns, and our water pump and filters and washing machine would sit on the slab extension. These were actually shown on revised drawings I sent him via email a few weeks ago, but he had not printed them and given them to his workers on site. Not a problem he said... "I will fix it tomorrow".

-

-

-

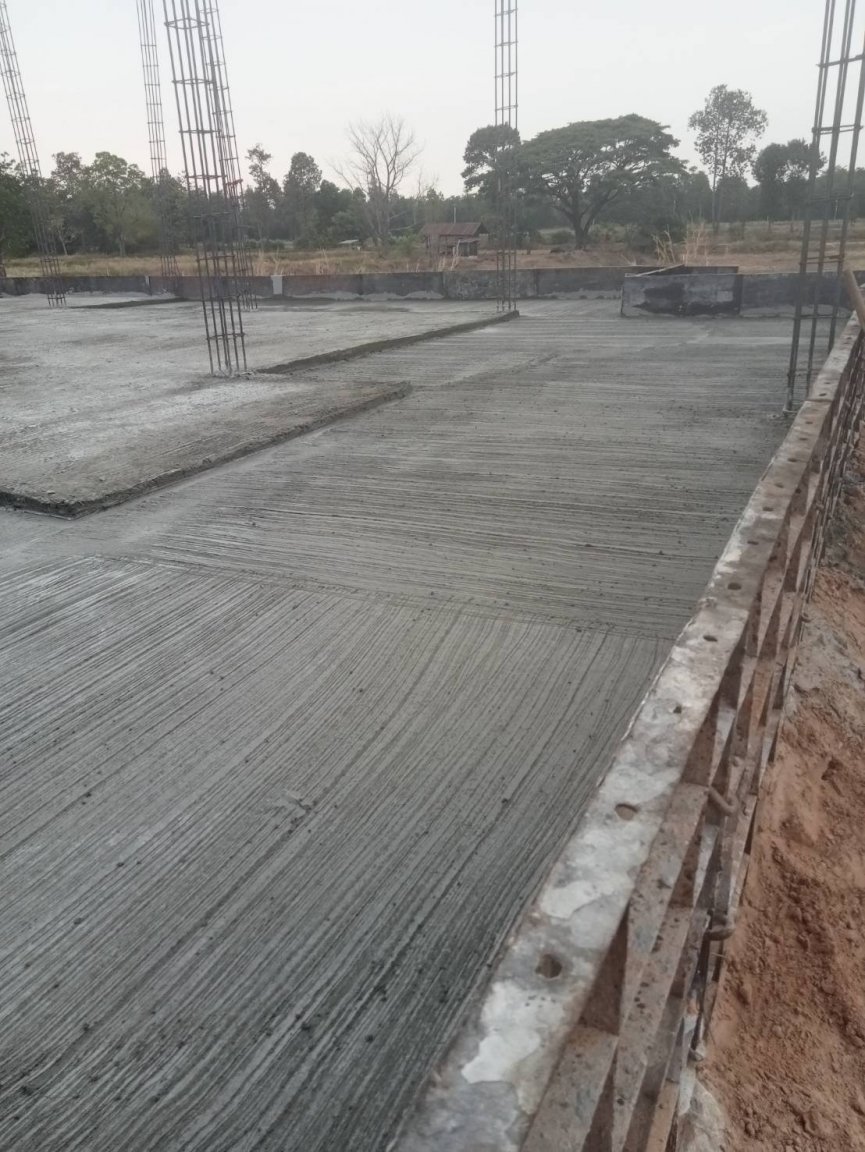

A few days later (April 1) and the build is really coming together nicely. All the columns are straight and vertical and wrapped in plastic to prevent drying out too quickly (they are using a laser level), and we arrived just after the concrete floor for the carport had been poured. I did ask the builder what size rebar or mesh he used as I was concerned that he had not listened to me when I explained that we wanted to deviate from the architect's design and wanted stronger reinforcing as we planned to install a couple of water tanks in there. I need not have worried... he said that he used RB12 rods @ 150mm ctrs... not a problem... you could park a Sherman tank on top of that!

-

I hope so too! Some of them are on a decided lean at the moment... I will be meeting with the builder on site on Saturday, and I will be bringing my laser level. The AAC blocks are scheduled for delivery on Saturday too so if his crew does not have one, they can use mine. The uPVC windows and doors have been ordered, but the final dimensions need to be verified after the final rendering is done, so it's important to make sure that the brickies leave correctly located and sized openings in the walls.

-

Today (Thursday 30 March) the formwork for the columns for the house and the carport are being erected, and the concrete will be delivered and poured tomorrow. The septic tank will also be installed today.

-

-

-

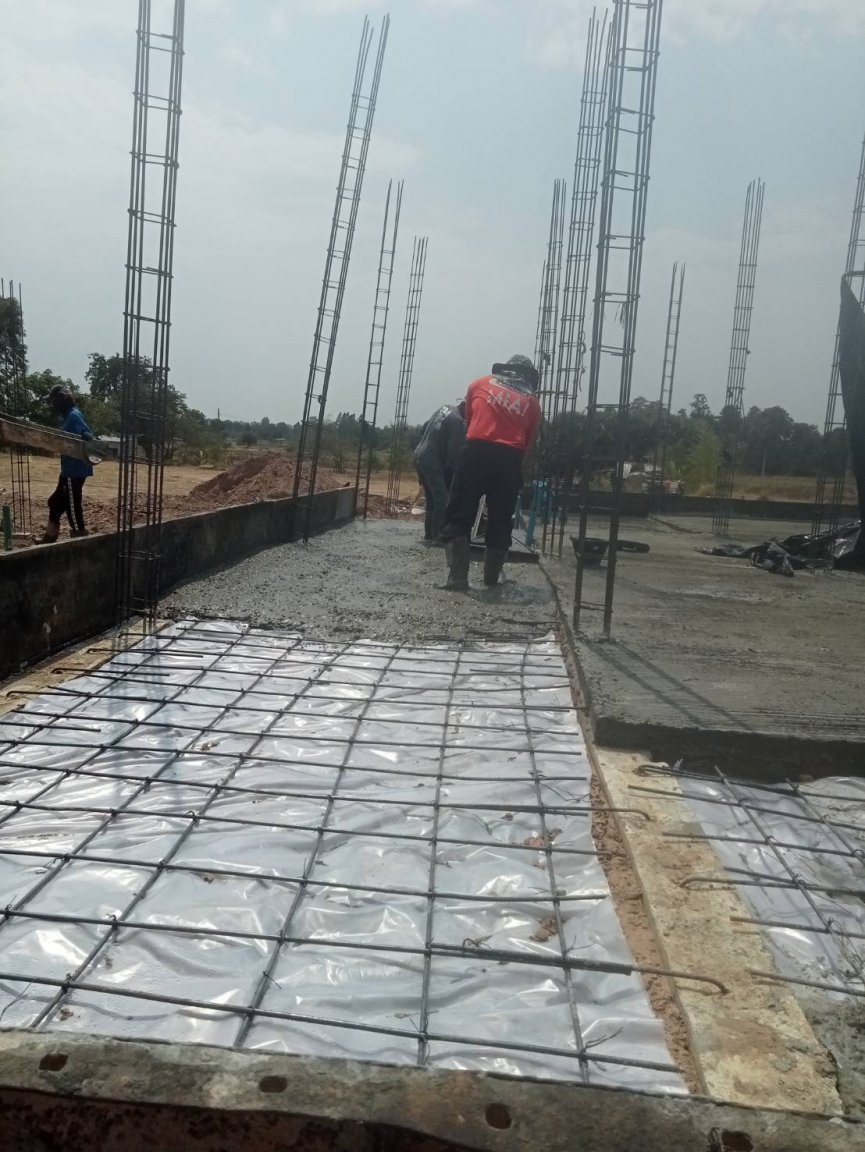

Yesterday the internal floor slab beams were delivered and installed... Also the waterproof barrier was laid in the bathroom and rebar mesh positioned and connected to the RC beams rebar. And by 5pm the external decking areas had also been prepared with waterproof barrier and rebar mesh...

-

Thanks for that tip... handy to know. As you can see, all of our PPR piping will be run either underground, or under slab, or inside the walls... so zero UV exposure. The house water storage tank, pump, filters, and PPR piping will be inside the carport which will be concrete block walled on the East and South sides, so zero UV exposure there too. All piping (PVC and PPR) will be painted if visible to match it's supporting structure (house, wall, carport etc.) as I really have an aversion to seeing (predominantly blue) piping everywhere, so that should increase its UV resistivity.