-

Posts

1,294 -

Joined

-

Last visited

Content Type

Events

Forums

Downloads

Quizzes

Gallery

Blogs

Everything posted by Encid

-

I think you have me confused with someone else... I have never mentioned CLC blocks in any post in any topic on this forum. The Q-CON Handbook calls it a mortar, not a glue... and in any case if you read my post again you will see that I quoted that information from the website I referenced (and linked to). You want to argue? Take it up with the website I referenced.

-

Good idea... I will incorporate that into the Guest House access steps too.

-

That is also supported by this website as AAC blocks are very porous: "Where mortar has been used between each brick, you should wait for 4 to 6 weeks to cure properly before applying the paint system. The curing process for mortar is important as it allows the alkalinity content to drop to a level where it won’t affect paint adhesion. It also ensures the moisture content in the mortar falls below 10%, and the time allows efflorescent salts to migrate out of the mortar. There are ‘green render sealer’ products that are available to minimise this curing period, but allowing the mortar to fully cure is recommended for best performance of the paint system. Oil-based prepcoats should be avoided on masonry surfaces even after curing, as the alkalinity of the surface reacts with the alkyd resin of the paint and affects adhesion. The Australian Standard AS/NZS Guide to the Painting of Buildings specifies only two coats of a quality acrylic exterior topcoat is required for exterior brick, FC sheet, concrete, masonry, cement render or AAC blocks (Hebel). It also states that additional prepcoats, topcoats or both may be required depending on the substrate colour, texture or porosity. For this reason we recommend a 1 x Prepcoat and 2 x Topcoat system as best practice." The article makes good reading and goes into more details.

-

I was thinking the same thing... We will be conducting the blessing ceremony for the first footing/columns on Thursday 9th March at 9am. Hopefully that will dispel all the negative ghosts and leave us with only friendly and supportive ghosts.

-

I will ignore the first part of your post, as I think that @Muhendis has responded perfectly already... thanks @Muhendis In response to the second part of your post, did you read my OP that started this topic? There was no land acquisition... the farm belonged to my wife's father, and he donated part of it to his daughter, my wife. In actual fact we are only 1 year into the project and it was very busy in the early stages... building up the site with fill, building it up further when we thought it was still too low, drilling a bore down to the water table and installing a solar powered pump and overland pipeline to the existing pond on the property, connecting to the PEA domestic power supply and running cables and poles across the family-owned farm land to our building site, dealing with COVID, the family self isolating from the rest of the village by relocating to the farm, building them a temporary shelter, a toilet, a water tank and pump for washing and showering and cleaning... it's all been detailed in this thread. The highs and the lows... the mistakes and the dramas... the setbacks caused by nature vs corner-cutting... the journey is all here for anyone to read. Most of the year has been waiting for the land to settle so we could build on it, and of course planning and designing for the future... Guest House first so we can live there whilst the Main House is constructed, then a perimeter wall/fence and some gates, then the concrete access road, then a solar array for the Guest House carport roof and an ESS, then the Main House and pool, then another solar array and some more ESS, then we will start planning for the farm... alternative crops (to rice), perhaps fish and/or crustacean farming, fruit trees and vegetables and salad etc. There's going to be plenty of opportunities in the future, and we are both really excited and looking forward to it. I have drawn and discarded many ideas for both the Guest House and the Main House, and have now settled on designs that we both like and are practical for the environment there and our future lifestyle. I have even incorporated a ramp into the design for the Main House for future wheelchair access should it ever become necessary in the coming decades. I have also asked for (and received) many ideas and comments from the members of this forum in various topics, and my ideas have evolved and become consolidated over this past year as a result. Our build may not be typical for the Isaan region or to other people's taste or liking... but it is our build and I'm sharing it here primarily to get opinions and ideas, but also to show our families and friends from across the world (as well as locally) what we are doing and how we are doing it.

-

-

What a bitter and negative viewpoint. Did you read my reply to Karen on 20 Feb 2022? It was as follows: That was a year ago. Nothing has changed (except the design of the house). So now we have been happily married for more than 17 years. I have already built a house in Najomtien for my wife... it was built 15 years ago and we have been happily living there since it was built, so this house will be number two. Your bitter views are probably a result of your own self-admission... you "probably made every mistake it's possible to make in LOS" including marrying a Thai girl for the wrong reasons. Me? I was lucky. I chose a diamond... although she often reminds me that she chose me first!

-

Don't you mean "gyp board" as in gypsum board? Due to its inherent fire resistance, gypsum board, commonly known as drywall is the premier building material for wall, ceiling, and partition systems in residential, institutional, and commercial structures in both Australia and New Zealand.

-

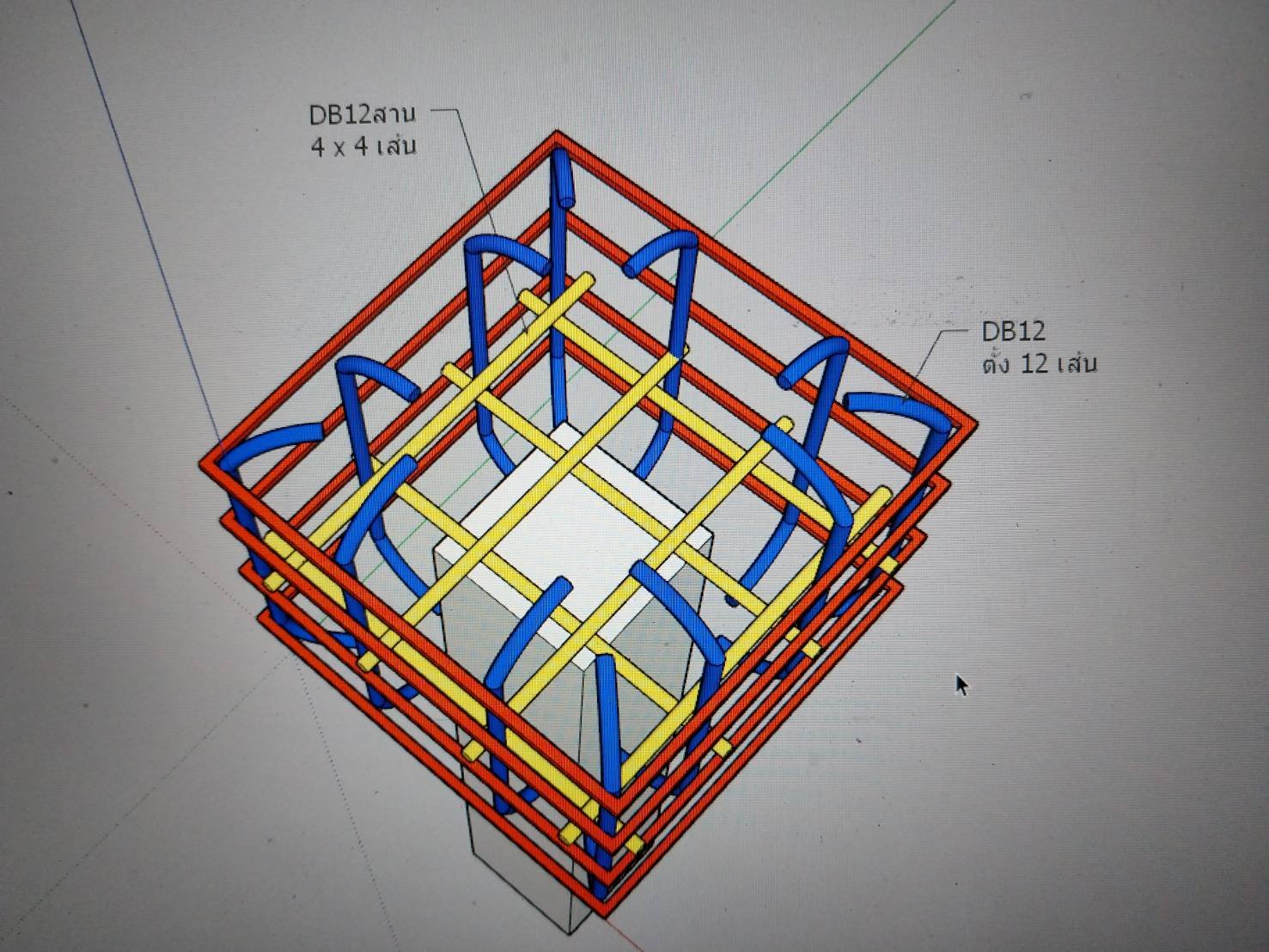

Our builder has also been busy off-site at his Khon Kaen workshop with workers bending and cutting and tying the rebar for the footings which will be welded to the reinforcing steel inside the piles. These guys are strong!

-

Meanwhile our builder has been busy dismantling protection/storage sheds at another building site and relocating and erecting them at our building site. The will give the workers some shade and protection and somewhere to eat their food and drinks and rest during the day. The actual camp for the workers will be located down on the farm, so their personal effects, washing, etc. will be about 80m from the work site.

-

If the weather this year is anything like last year (with lots of rain and localized flooding) I'm anticipating at least a 30% settlement. I am not concerned because there will be no building constructed on that land, and we can further back-fill it in the future. No... the original plan was to leave it unfilled as there was already a 20cm dia PVC drain at the end of the wall leading to the rice field. That drain is now probably blocked, but I do not anticipate a lot of rain water is going to cause a problem for that small volume of land between the concrete rings retaining wall and the concrete slat wall. We are only talking about a total surface area of 12 cu.m. over a 60m length after all. Did you see the size of the truck (18-wheeler) that delivered our piles a few nights ago? See the photos above. They don't come much larger than that in our area due to the small rambling country concrete roads. After the construction of the Guest House is complete, our plan is to survey the land for the location of the Main House, and drive in pegs for the pile locations. The 4m wide access road will also be located and pegged. Then we will do some localized soil preparation, lay down some geotextile, and prepare some boxing for a steel mesh reinforced concrete road from the front entrance at the government road through our building site then down to the farm. I do not anticipate that trucks or other farm harvesting machinery will have any problems accessing the property after rain. Not required. There will be a drain under the ramp, and geotextile laid over the top of the prepared soil, then the whole thing will be concreted (with steel mesh to reinforce the concrete on the road section. We will then build a formal gate and some decorative columns to flank the road entrance. We are considering a remote controlled electric bifold gate (similar to the image below) as it will be on a slope and these types of folding gates are the only gates that work on a slope. Other suggestions are welcome... Currently it is a 1.6m rise over a 10m run, which works out at an angle of 9°, so hardly difficult for any vehicle to climb but slightly more than 7° which is the maximum parking slope permitted in the International Building Code (IBC)... but, this is not a car park and neither is it Koh Chang or Phuket, both of which locations I have personally driven on many occasions and both locations have public roads with slope angles far in excess of 9°. And of course the site access ramp will have transition slopes so our Ferrari-driving friends will not scrape their cars on the concrete. We won't bother transitioning the ramp down to the farm... no Ferraris will be going there.

-

Too late to edit... my wife informed me today that the cost differential was actually 50 baht per pile, not 100 baht. And delivery was free because we bought more than 20 piles.

-

It looks great!

-

Actually we are thinking of renting/leasing it. We have heard via the jungle drums that our formerly troublesome neighbour has fallen on hard times, and although her pride is preventing her from selling the property, she is amenable to a rental arrangement. I would prefer a lease with a fixed term rather than an annual rental, as for sure she'd want to terminate the agreement if we made improvements. There's no hurry for now... but the seed has been planted and I will just sit back and see if it grows...

-

1 month later and it still looks OK... no rain yet though...

-

And this morning (3 March) the pile driver arrived and started work... (Please no disparaging safety related comments... I know... I know... ) 1677835576193.mp4 1677835589091.mp4 All the piles are being driven into the land that has been settling for the past 11 months, and you can see that it is pretty slow work. We opted to go with 26cm x 26cm x 6m long piles rather than 22cm x 22cm, as there was only a cost differential of 100 baht per pile (delivered) and it costs about 1000 baht per pile to drive. There will be 27 piles driven. None are being driven into the freshly filled land that we reclaimed behind the retaining wall (which hasn't moved at all by the way... but fingers are crossed and we're keeping a close eye on it.)

-

-

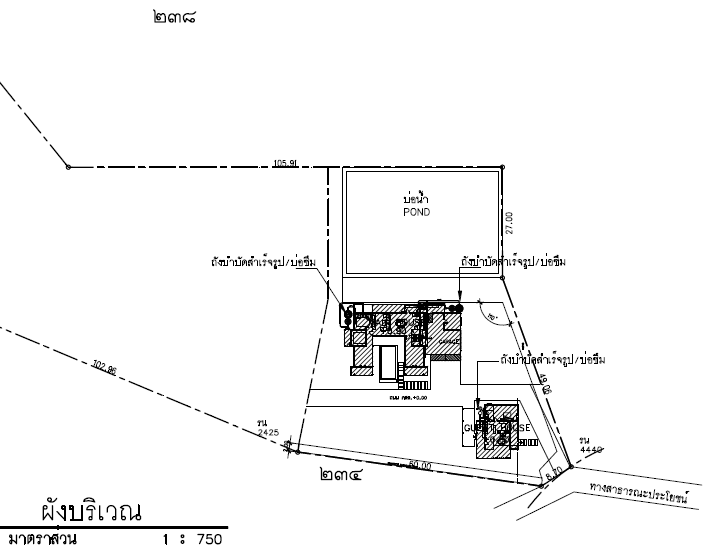

And from the air... The pegs (or wooden stakes) that are not painted represent the 4m wide access road.

-

Well another month has passed and we have finally signed a contract with our builder on 22 Feb for the construction of the Guest House. After all the discussion we had in this topic about how to effectively seal a flat roof, we had further discussions with our builder we are now going to be building an alternative roof... one that keeps the same appearance or profile from all sides at grade level up to 4m high, but will actually be a sloping Bluescope steel PU insulated roof behind an AAC block facade on all sides, so for all intents and purposes it will appear like a flat roof (unless you use a cherry-picker or a drone!). The facade will also hide a large gutter to collect the rain water and discharge it out through the facade via 10cm dia downpipes. Our builder revised his BOQ based on this design and was able to achieve an overall 20% cost saving over the original price (based on reduced rebar steel in the roof and supporting columns) as well as an improved construction schedule. We paid a deposit so he could order the piles then went to visit the site to survey the land and decide where the piles were to be driven. I wanted to maintain a width of 4m for a road access from the government road onto our property, then maintain that same width road down the middle of our elevated land plot and down a ramp to the farm, so that was one of the governing aspects to locating the building. The second governing aspect was that I wanted both the Main House (future) and the Guest House to be constructed parallel to the existing pond, which runs North-South on the property. The fact that the boundary concrete slat wall is about 8° off the N-S line doesn't really concern us as it will hardly be noticeable in a couple of years time (especially after our perimeter bougainvilleas get established). The third governing aspect was to try to get the Guest House as close as possible to the Northern boundary, in order to get some "separation distance" between it and the Main House. This will provide some privacy for all of us who will be living there (actually a lot more privacy than that which is available in the village at the moment). It was hot out there surveying, and we had to move the pegs a few times so we could achieve the setout criteria listed above, but we finally completed it in about 2 hours and sprayed painted all the pile location pegs with bright pink paint. The piles were due to be delivered on 1 March.

-

Link to SCG roofing materials.

-

What is the volume of your pool (in cu.m.)? What is the make/model/hp of your pump? What is it's flowrate (in cu.m/hr)? What type of filter do you have (sand/glass)? Efficient pool water filtration is dependent on several things... firstly and most importantly, water turnover. Your pump should be able to turnover the volume of water in your pool at least once in one day (8 hours running time - usually from 8am-midday then 2pm to 6pm.) These hours are considered to be optimal for filtration and also the 2 hour rest during the hottest time of the day means less loss of chlorine (whether you have a chlorine or salt based pool). Second, glass media in filters tend to result in a clearer "sparkly" water finish, as their particle size is much smaller then sand, and don't wear down so much over time, but the downside is that you will have to backwash the filter much more during cleaning (vacuuming) the pool as more debris is trapped by the filter. I suspect that your cloudy water is a direct result of not having enough water turnover based on reduced pump/filtration times. As suggested by other members, a solar solution is perfect for subsidizing your electricity bills... you only need to run your pump/filter during daylight hours and that same daylight can produce the required energy to run your pump.

-

Have you tested your water yet? I didn't see any mention of filters in your installation.

-

Can you please provide a link to that website?

-

Thanks for all the responses everyone... they have certainly given me a lot to think about. I am now considering a ground-mounted solar array instead of roof-mounted, so no penetrations or damage will happen to the roof membrane (if we go with an RC roof as designed). After chatting with our builder, we are also considering an alternative roof too... one that keeps the same appearance or profile from all sides at grade level up to 3m high, but will actually be a sloping Bluescope steel roof behind a concrete facade. An early estimate gives us an overall 20% cost saving (based on reduced rebar steel in the roof and supporting columns) as well as an improved construction schedule. More to come...

-

Solar power, can it be done DIY?

Encid replied to Sophon's topic in Alternative/Renewable Energy Forum

That is a nice, neat installation... well done!