-

Posts

1,294 -

Joined

-

Last visited

Content Type

Events

Forums

Downloads

Quizzes

Gallery

Blogs

Everything posted by Encid

-

Where can you buy new rubber pads, or did you just make them yourself? One of our AC unit compressors is a bit noisy too... 15 years old.

-

It depends on your panel sizes and how many you want to install. For example, 455W mono panels weigh 24.6±3 kg each, but 335W poly panels weigh only 22.5kg each. Not so much, but it does add up (cost-wise too). Don't forget to factor in the weight of panel supports (so you can get them facing South at the right angle for your latitude) plus the weight of the people who will be installing them, and of course the people that will be maintaining them later. Good idea for the roof, as it will cut down on rain noise inside and keep some of the heat out, but why would you bother with the walls if it is to have an open (East-facing?) section for your vehicles to enter/exit?

-

You should be able to buy a similar stainless steel sheet mitred bend (and other ducting, whirly-birds etc.) at any stainless steel shop that sells cooking benches, range hoods, etc. Plenty around in Ekkamai IIRC.

-

I've heard that mothballs (naphthalene) make a good deterrent, so I'm trying this method at my place now. I put about 20 mothballs into plastic bags and then sealed them with rubber bands. I then punched about 50 holes in each bag using a toothpick, then placed them inside inside the AC compressor housing as well as the fuse box inside our pool pump house. Seems to be working so far...

-

Despite a small work crew and mid-to-high forties daily temperatures, the walls are continuing to rise up. My niece takes her mother and all the family dogs out to the farm in the late afternoon to take photos for me... it's still pretty warm but not as brutal. The dogs seem to enjoy the freedom and exercise despite the heat and the dust. Everyone is praying for rain... maybe this weekend?

-

How about a solar car port on a budget?

Encid replied to Crossy's topic in Alternative/Renewable Energy Forum

@Crossy, how is your system performing in this heat? Yours is not exactly in a temperature controlled environment is it? Any problems? -

I think that all the levelling that is mentioned in the manual is going a bit overboard, particularly if the walls are going to be rendered then painted afterwards (which ours will be). Our builder is using a single thin bed mortar layer of about 3-5mm only, and I'm happy with that as ours are not load-bearing walls.

-

-

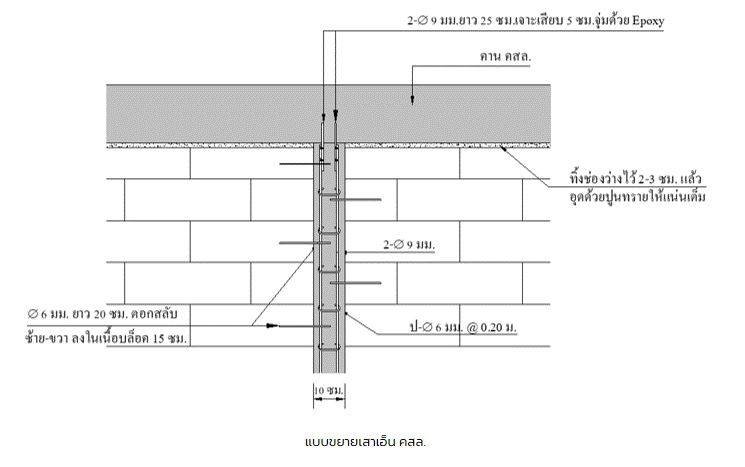

Some of the building team are staying on and not going home for Songkran, so our build is continuing (despite the heat), albeit at a slower pace. It is good to see that they are following the recommendations provided in the QCON Handbook for fixing the AAC blocks to the RC columns. It is also good to see that they are using a laser level as well as the string lines for their work...

-

I was in Pattaya this afternoon and it is full-on water throwing outside the beer bars on Beach Road. Quite a few Russian tourist getting upset at getting wet, but that only makes it worse for them! Complain, and you're a target for everyone! The Songkran fun has been missed for the last couple of years.

-

I found this section from degrub's reference article particularly interesting... "Cloud-to-ground lightning strokes initiate high in thunderstorms, miles above the surface where ground objects have no effect. Even after initiation of the discharge, the downward-moving stepped leader is 'blind' to objects on the ground until it is very close to the ground, within 50 to 100 feet. At that distance, lightning will strike within the very small area it is already descending in, regardless of any devices nearby that claim to divert or prevent the strike. For example, a photograph exists of a lightning strike to the Merchandise Mart building in downtown Chicago. Merchandise Mart is very close to the 1,700 foot tall Sears Tower, yet not even the Sears Tower influenced the ground connection of this close cloud-to-ground stroke." As a lightning bolt's ground connection is already 'set in stone', so to speak... nothing short of a large telecoms tower or skyscraper will attract or deflect the bolt away from its target... which is a factor of the position of the storm rather than objects on the ground. I wonder if it's worth it?

-

Where can you get stuff like this? Do they work? My concern is that our new build is out in the middle of the rice fields of Isaan, and will be not only the highest structure, but the only structure around for several kilometers and are highly likely to get struck by lightning during those violent summer storms. A direct strike would take out everything and anything electrical in the house... currently there is no surge protection (no pun intended).

-

Some of the roof steel has been delivered, but not all... So the workers have started on the erection of the AAC block walls. The building will have a double cavity wall on the west side only, all other walls will be single 75cm blocks. The south side will be fully shaded by the roof over the outside decking and the Thai kitchen, which in turn will be shaded by the carport.

-

Some more work in progress while we wait for the roof steel to be delivered... the 2" PVC ring main around the pond was laid in a trench, and was also run across to the retaining wall where it will supply the guest house water tank. Power supply cables were also run inside a 2" PVC pipe in the same trench, then the trench was backfilled. We will clearly mark the route of the underground piping so that we don't accidentally dig it up or break it in the future.

-

I do have PEA supplied 220V AC power available at the storage tanks area... it powers the Mitsu water pump. Could that power be utilized to provide the necessary current to power the relay?

-

A bit of research led me to this website and Google Translate gives me the following: ADVANTAGES OF DC DD SOLAR PUMP SUBMERSIBLE PUMPS 1. Permanent magnet brushless synchronous motor: efficiency is improved by 15%-20%, saving energy. Reduce the use of solar panels 2. 304S/S pump shaft 3. Brassoutlet/Connector/Oil tank. 4. Japanese NSK bearings, service life is 3 to 5 times longer. 5. Model motor base Doublebearing Able to work under greater axial loads 6. Alloy seals: Longer service life and high reliability. 7. Motorcoil is made by automatic winding machine, with centralized winding technology, motor efficiency is greatly improved. 8. Intelligent water shortage protection: The pump will automatically stop working when there is no water in the well and automatically start 30 minutes later. Controller: has the following properties (1) Waterproof grade: IP65 (2) VOC range: 48V regulator : 50V-110 V; 72V regulator : 50V-150 V; 96V controller : 90V-210 V; 110V controller : 90V-210 V (3) Ambient temperature: -15 ℃ ~ 60 ℃ (4) Maximum input current: 15A (5) MPPT function, higher solar utilization rate. (u6) LED shows the working condition of power, voltage, current, speed, etc. (7) Frequency conversion function: it can automatically operate with frequency conversion based on solar energy, and the user can also change Manual pump speed (8) start and stop automatically (9) Waterproof and anti-leakage: double seal effect. (10) Soft start: No excitation current protects the pump motor. (11) High Voltage/Low Voltage/Over Current/High Temperature Protection (12) Product warranty 2 years Can any of you electrically-minded gurus use this information to tell me how I can automate the start/stop of the pump from our storage tanks 200m away?

-

In our current house (15 years old) we have a dedicated breaker for every water heater, every air con unit, electric oven, electric hot plate, range hood, and pool pumphouse. The GPO's are shared across 4 breakers, and the lighting is shared over another 4 breakers. We have an ufer grounding system in the footings of the house.

-

Well my niece came through with photos of the PV solar panel powered submersible pump control box... powering a 750W pump. Here it is in the off position: And here it is in the on position (with lights flashing apparently):

-

Well it looks like I will have to wait another day before I can get a photo of the control box... my niece decided that she'd rather go to the market in Phon with her friends this afternoon instead of going to the hot and dusty farm. She is home for the holidays from her (uncle funded) University studies.

-

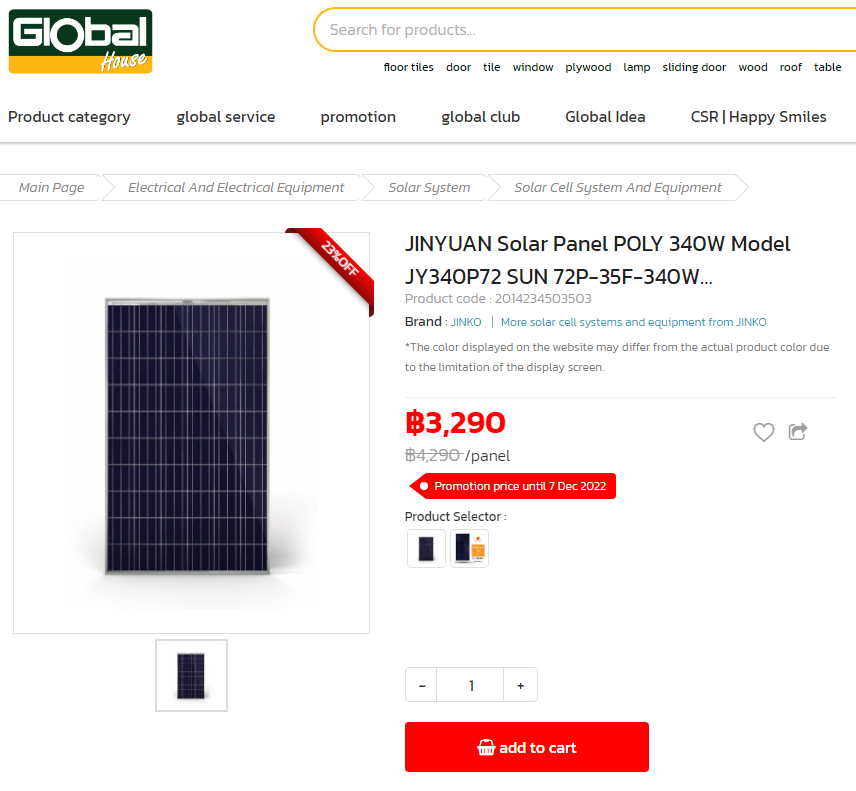

One year later and prices have definitely changed... Global House no longer stocks the 340W Poly model from Jinyuan, they now carry the 335W Poly model instead and it's 660 baht more expensive. I thought that prices were coming down...

-

Sounds logical to me. My own experience with PVC ball valves is limited to those in our pool pumphouse... they get operated 2-3 times a week but they never see the sun so no direct UV exposure. I have not had a problem with any of them in the 15 years that we've had the pool.

-

May I ask why you used brass gate valves and not PVC ball valves?

-

I don't have a specification for the box... no documentation at all. I have asked my niece to take a photo of the internals and send it to me this afternoon.

-

You are correct... I am not electrically minded at all with only basic knowledge of that field of engineering, so any suggestions would be highly appreciated. I don't have a photograph of the control box but I have asked my niece to take a photo of it later today. I do have a photo from when it was installed exactly 1 year ago... the control box is mounted directly under the PV panels which are directly over the bore/pump. 2 cables were originally connected to it and run alongside the pipeline before it was buried... the cables went to a switch at the power pole at the pond but it never worked... the guy who installed it said that the distance was too far. I will look for them when I re-visit the farm again after Songkran.

-

My wife likes to have clean toilets in our house. Currently (living in Najomtien) we have 3 toilets inside the house, and another which serves as the maid's toilet in the garage. We don't have a maid because my wife likes to do all the cleaning herself. Currently she is using a product called Magiclean to clean all the sanitary ware, as she is happy with the results. I however worry a bit about the chemicals in this product (which are supposed to be 99.9% deadly for bacteria) killing all the "good" bacteria we have in our septic tanks. Sure it is diluted considerably by the time it is flushed into the septic tank, but would it be diluted enough not to have a negative effect on the "good" bacteria? Anyone have any experience or suggestions?