-

Posts

1,294 -

Joined

-

Last visited

Content Type

Events

Forums

Downloads

Quizzes

Gallery

Blogs

Everything posted by Encid

-

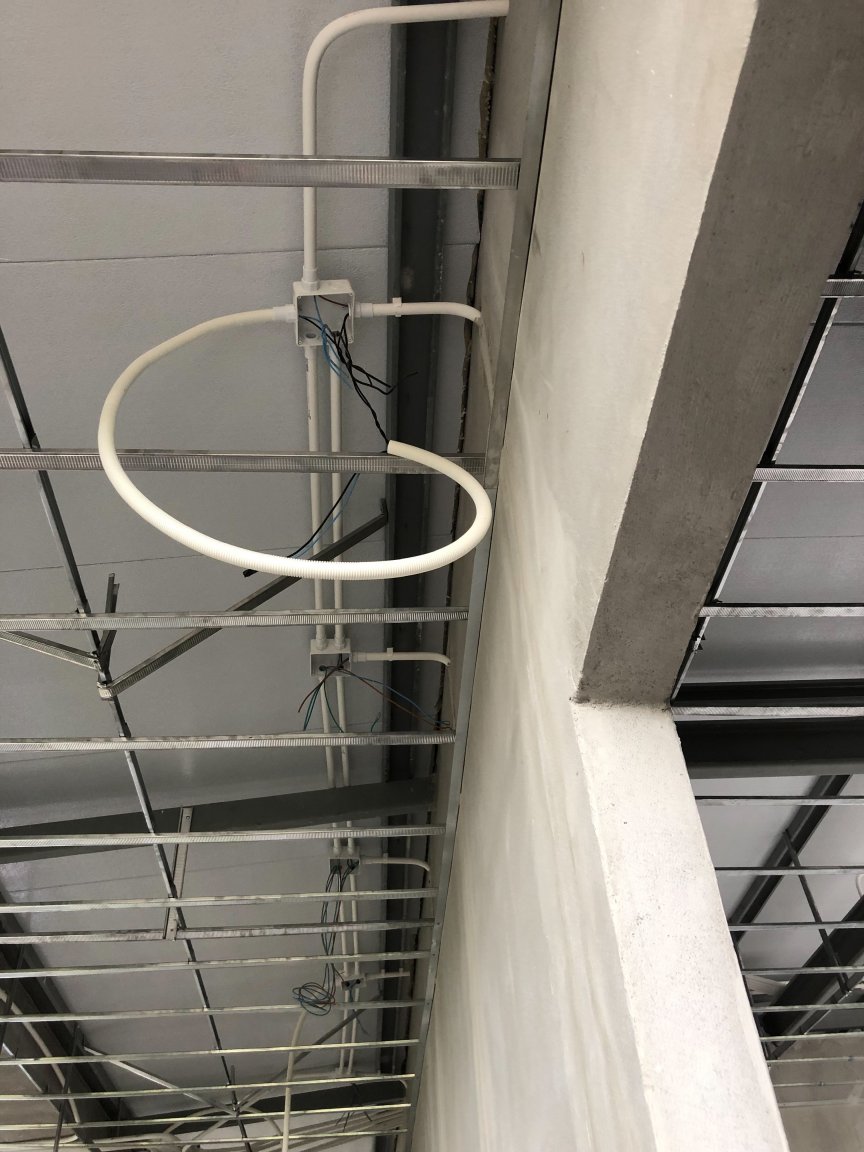

The electrician is also now on site and he is busy cutting tracks in the walls to hide his conduits.

-

I'm not sure of the fixing details yet, however I have asked that the screen section are to be made removable. More to come on this subject for sure...

-

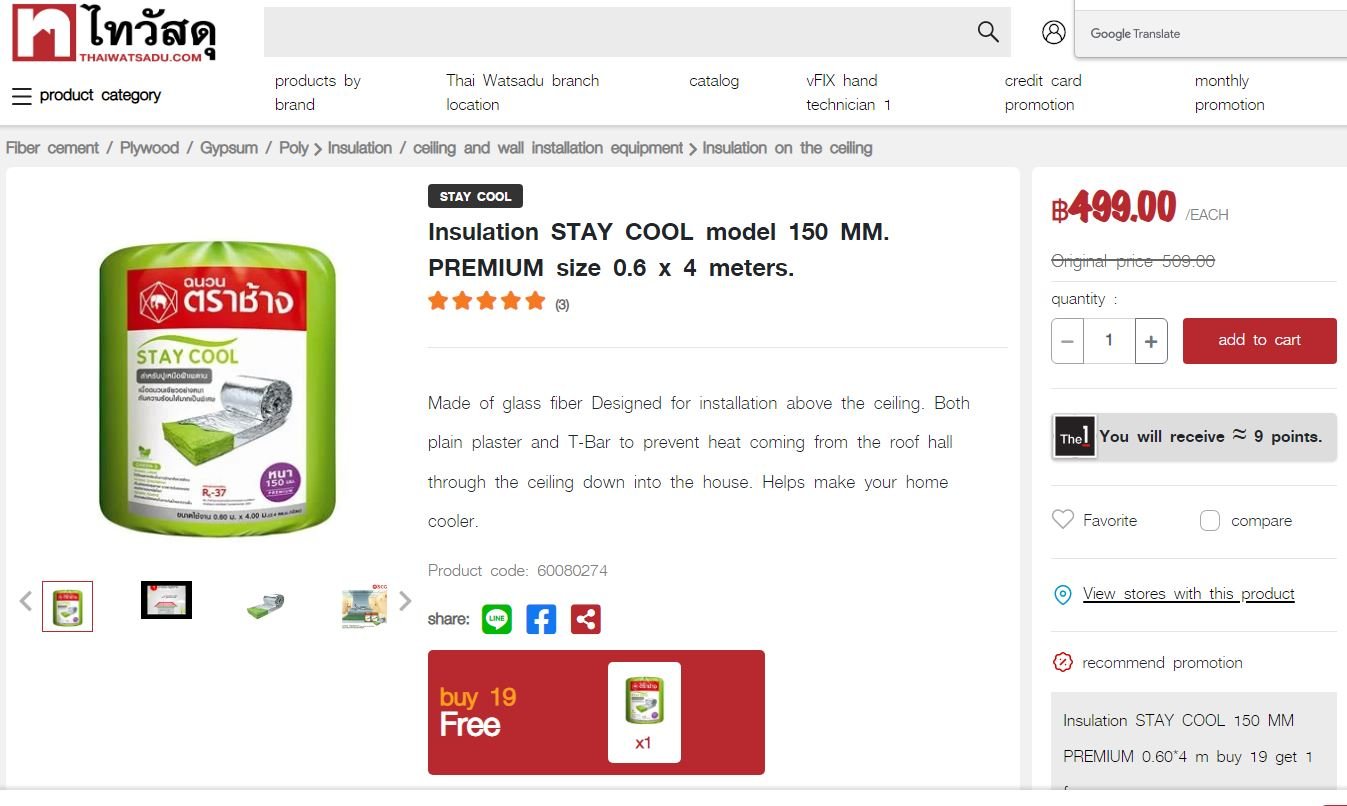

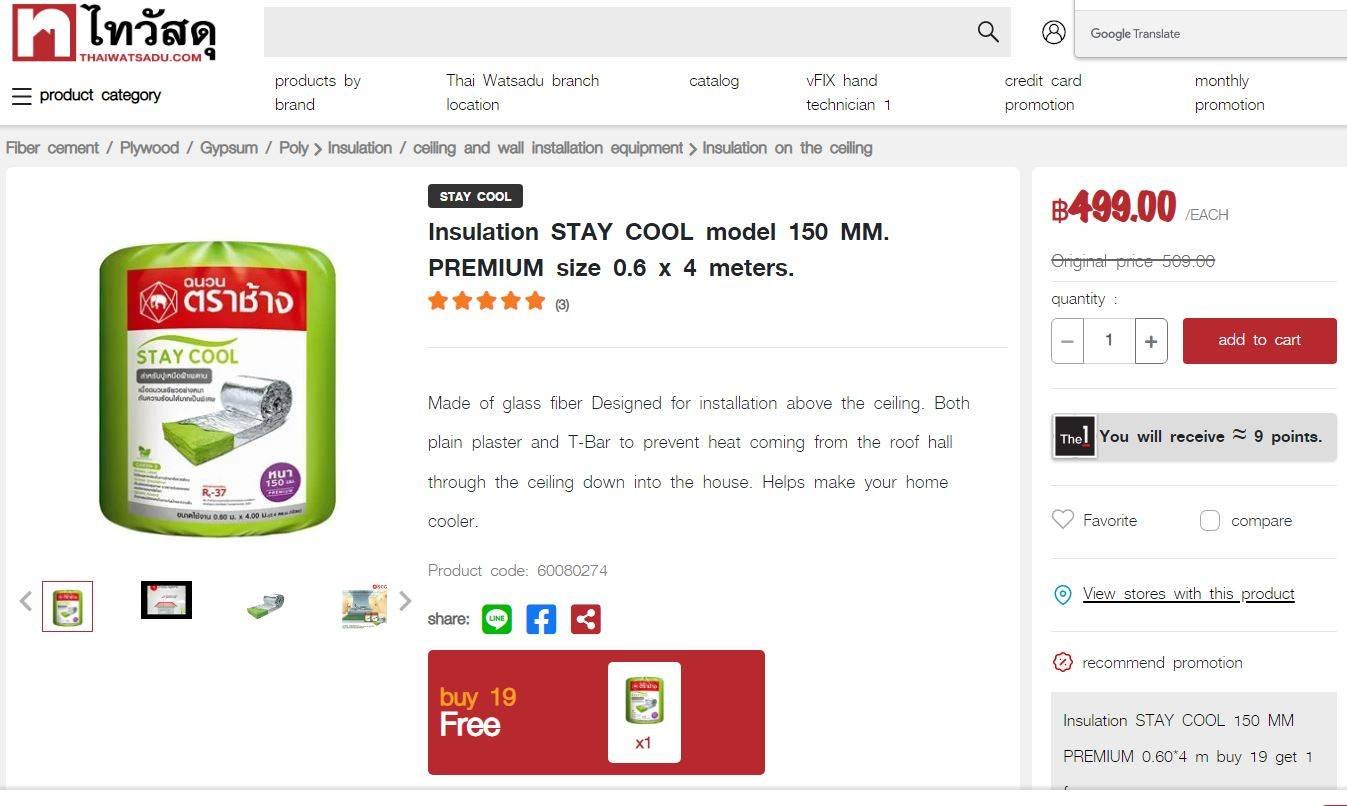

As the real roof is concealed by a façade (see the aerial photos a few posts ago), we cannot really introduce any air flow in the ceiling cavity... that is why we have opted for 6" thick SCG "Stay Cool" insulation to be laid on all ceiling surfaces. That, combined with the PU foam layer underneath the steel roof sections should provide us with adequate thermal (and acoustic) insulation.

-

You guys were right about our tiler not knowing how to use the tile levelling system properly. I spoke to our builder about it and he was on site the very next morning to 1) check the tiles already laid, and 2) assist the tiler in understanding exactly how the leveling system is supposed to work. He sent me back some photographs and assured me that all the tiles that have already been laid are perfectly level and lip-free, as his tiler was "a good craftsman" and has given me his personal guarantee that we will not have any problems. I will be heading up there again in a couple of days to check it out first hand.

-

I have a Hayward 1.5hp pool pump for filtration/circulation, and another Hayward 1.5hp pool pump for the waterfall (which we rarely use). Each uses 1.1kW per hour of operation, so if you are filtering your pool for 8 hours per day (8am-midday, and 2pm to 6pm) then your daily power consumption will be 8.8kW. Installing a solar system just to power the pool pumps (during daylight hours) is an option you may wish to investigate.

-

555... My wife wanted a blue roof but I insisted on a white roof.

-

And now that it is more or less weather-proof inside the building, today (25th June) the tiling work has started, although we are no longer there to see it in person. SIL is now charged with providing us with daily progress photos as our niece has gone back to university, so the quality of photos is not as good as before. We bought the tiles over a month ago at Boonthavorn and they were delivered to site last week. Good to see that the builder heeded my request to use tile spacers and wedge-based levelling system for the tiling work. A line has also been etched (using a laser level) on the walls 1m up from the FFL (finished floor level) so the uPVC window and door manufacturer can come and perform his final site survey and measurements for the windows and doors.

-

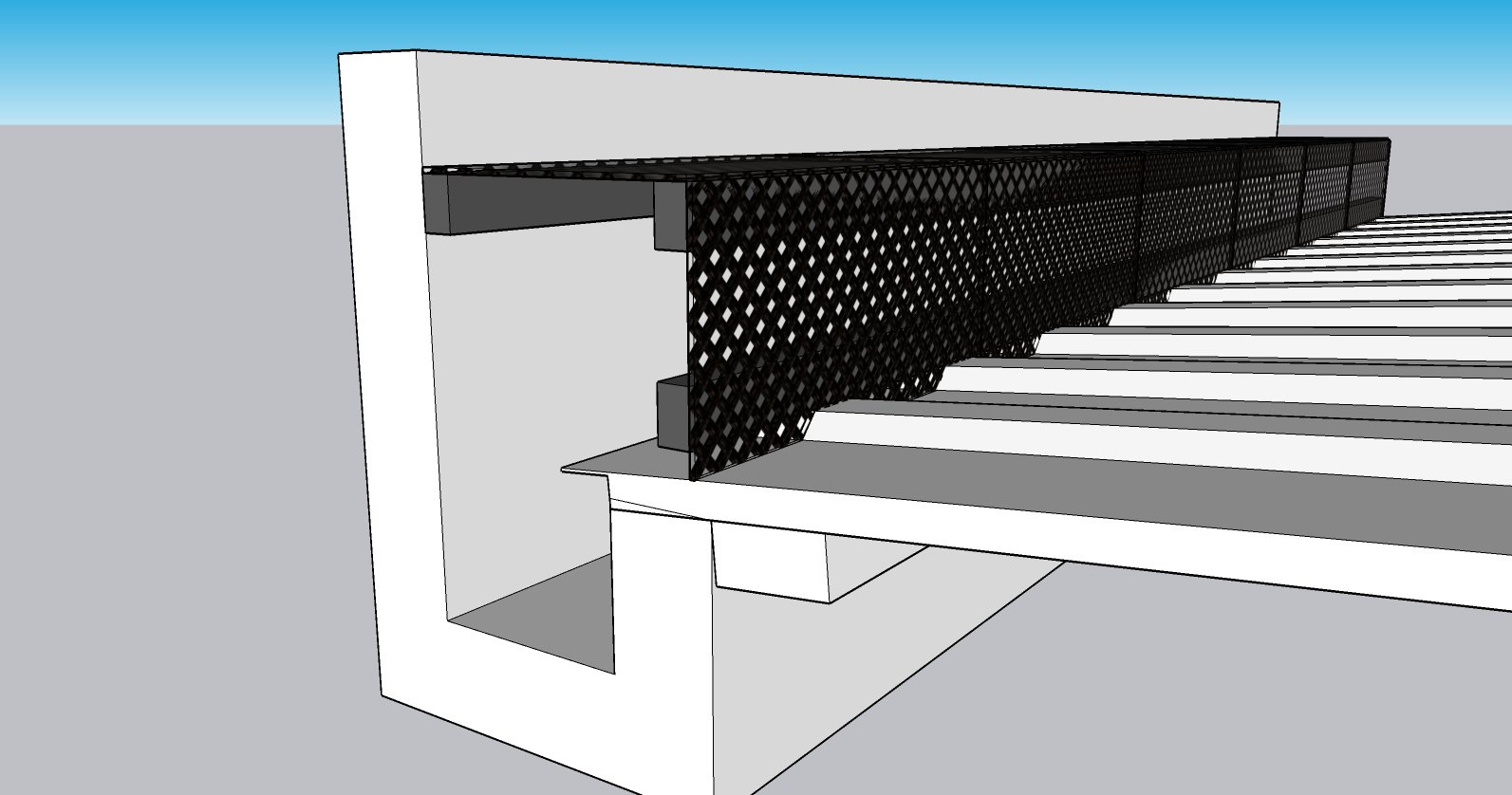

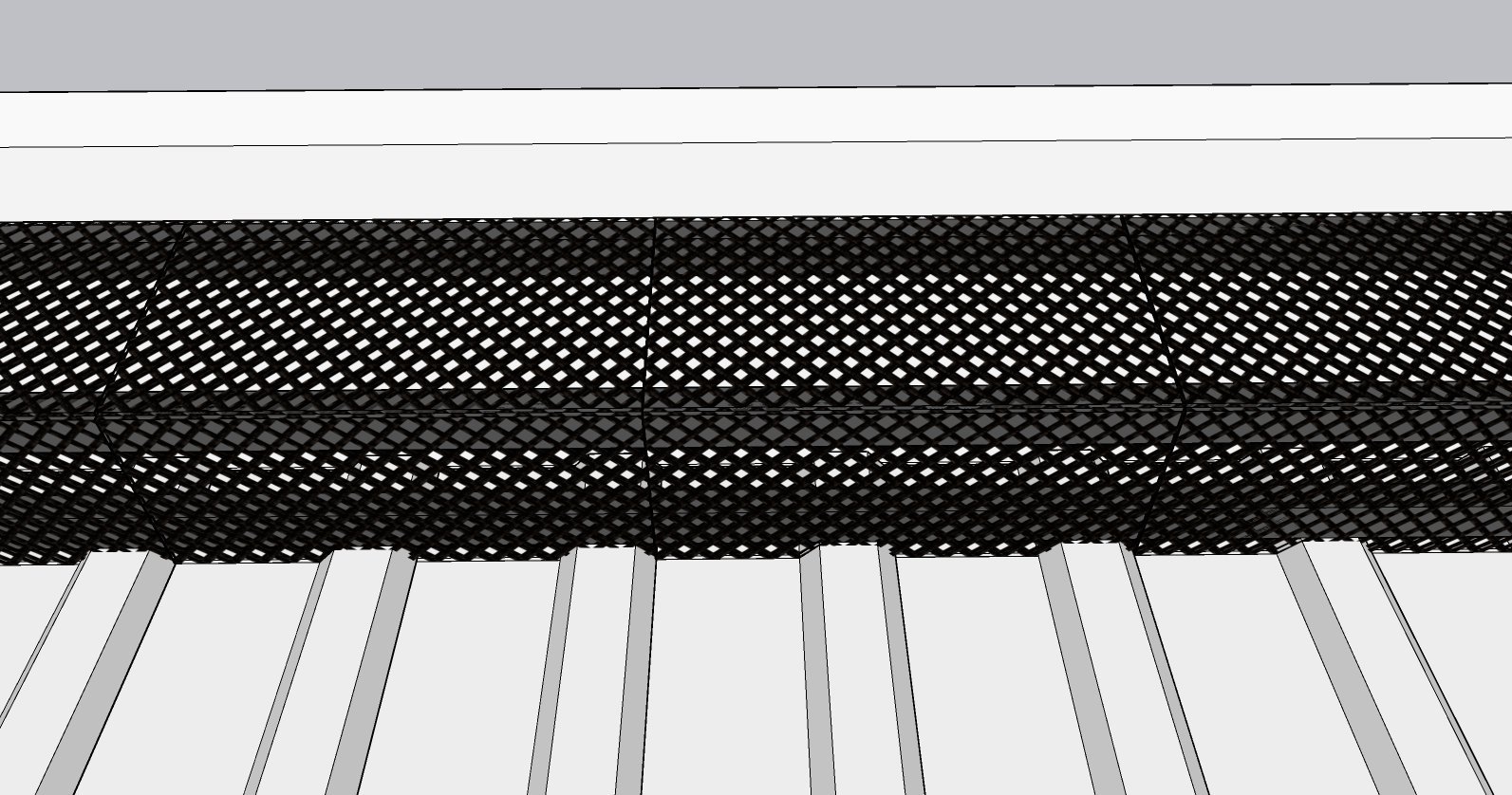

One small problem... birds! Many birds of all shapes, sizes, and varieties are now trying to make nests in the gutters and also pecking out the PU foam on the carport roof as well. So we have come up with some solutions. For the exposed edges of the carport roof we will install pieces of Conwood that have been cut to match the profile of the steel roofing material. For the gutters we will install some expanded aluminium mesh sections that overlap each other and are fixed via SS screws to 2" x 1" steel box sections that will run the full length of the gutters. Only the steel box sections will need painting, as the fixing screws and the mesh are corrosion resistant. We looked at using polypropylene bird mesh netting, but it is really only good for a few years before it degrades in the strong sunlight. This is a much more durable solution that will hopefully last for 10 years or more.

-

And when we visited site on the 20th June we could see that the roof was nearing completion... only the sealing and flashing to finish off. From the air you can see how the real roof is hidden by the AAC block façade, and how the guttering/drains system works.

-

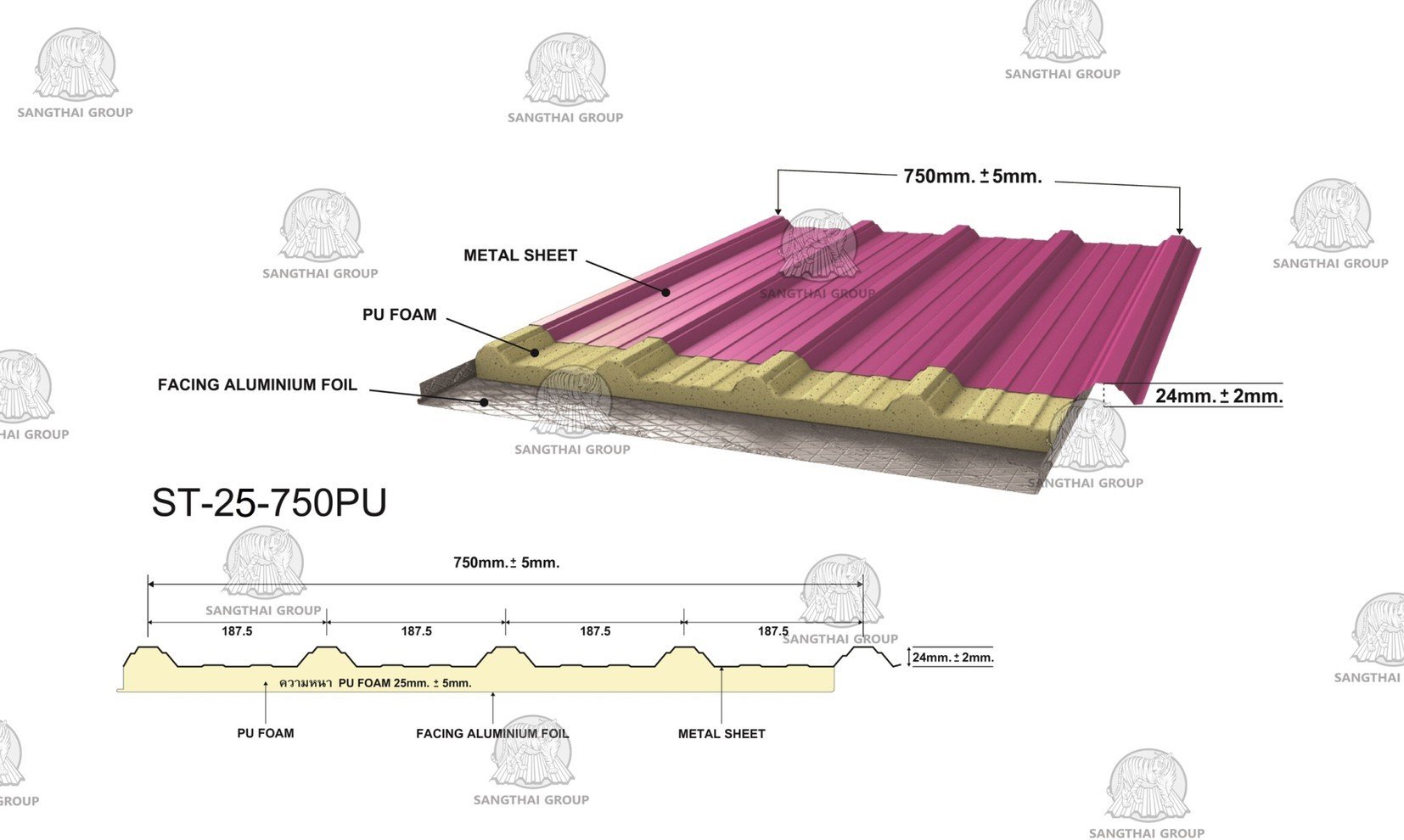

And on the 16th of June some roof sections were finally delivered and erected. The carport is being done first so the area can be used for storage and also shelter from the rain. In the end we opted to go with the 25mm thick PU foam backed metal sheet roofing from Sangthai Group. If we opted to go with the 50mm thick PU foam we would have incurred an additional 52,500 baht. With the savings from the roof material we will be spending about 30,000 baht on this good stuff instead:

-

Well it's been a couple of weeks since my last post and I have visited the building site twice in that time. I am very happy to advise that there no "drummy" rendered walls... both inside and outside the house. But as with all projects not everything has gone to plan... not a disaster but some rectification work has been needed to be done in a number of areas, particularly with the water piping. Firstly, at the raw water storage tanks the plumber decided to reduce the outlet of the pump discharge piping from 1" to 1/2" before it went into the 2" ring main around the pond. Why? Because that's how it's done in Thailand! I spoke to my builder abut it and showed him where he could salvage most of the piping already in place but remove and replace the 1/2" reduced section to enable full 1" unrestricted flow to the ring main. He agreed with me without questioning, and was also scratching his head as to why his plumber would pipe it up like that! The next issue was the raw water supply to the GH. It was run underground in a 2" PVC pipe across the building site to the edge of our retaining wall, where I wanted it to branch in several directions... 1 to supply the water filters and water tank in the carport, and 3 more to supply 1/2" taps for watering our future garden along the retaining wall. After the filtered water fill pipe to the tank, all piping from the tank to the pump and then to the water distribution system in the house was to be D32 (1") PPR piping up until the wall outlets which would be 1/2" female treaded joints. So it was a simple concept (so I thought)... PVC piping for the raw water system, and PPR piping for the filtered water system. The PPR fittings required at the outlets are these ones: But somehow all of this got lost in translation (despite detailed drawings and schematics) and the plumber ended up doing this: He had connected the unfiltered raw water supply directly to the PPR distribution system for the house! I also noted that the fitting he used upstream of the tap in the photo above (which is for the washing machine in the carport) was actually D25 x 1/2" and that the D32 pipe had been reduced to D25, which made me suspect all of the other PPR water outlets in the house (whose piping by now had been covered up by cement render) and sure enough, they were all D25 x 1/2" too. I spoke to my builder who talked with his plumber and apparently he was unable to buy the D32 x 1/2" fittings at the shop he went to, so he bought reducers and D25 x 1/2" reducing elbows instead. I told my builder that this was unacceptable and they all needed to be replaced with the correctly sized components. I did test the water pressure of the hose connected to the tap in the picture, and it was strong enough to sufficiently fill our water tank (or a washing machine) so I told him that that particular outlet could remain as-is, however all the other water outlets in the house must be changed to the correct fitting size so we can get full pump water pressure and flow rate. He agreed with me without questioning. I am sure that he will have words with his plumber for not following the drawings and the specifications. We had a brief chat about talking with me first before deviating from any drawings and specifications, and "taking initiatives". If "initiatives" are deemed (by me, the customer) to be an improvement to the design or a cost saving, then they will be considered, otherwise there are to be no deviations at all... and my builder has agreed. We shall see...

-

OK I have progressed enough with my post count on the forum to be now labelled as an "Apprentice Member" which is proudly displayed underneath my username on the forum... but to be honest it's a little boring! But I see that some members have edited this to become something more interesting... like "Bull Powered Member" or "Displaying my Member" etc. I have looked at my profile to try to see where this can be edited but cannot find it. Can anyone please help?

-

Neither do I... we had an earth leakage from a Mex water heater in one of our rental houses that travelled via the hot water to the mixer faucet in the shower... every time you went to adjust the hot water you received an electric shock! In our own house we have Mazuma Redring units... never a problem in 15 years of use.

-

I haven't received the usual email reminder notification since my last successful online 90-day report back in December. I thought it had been a while since my last report, so I checked my emails and sure enough... no reminder and therefore no submission. My visa extension is good until August, but my reporting is overdue. What should I do?

-

In that case I will test the walls next time I am on site. First time that I will have taken a screwdriver to the building site... Thanks for the suggestions @HighPriority and @carlyai

-

I can understand how hot it could get inside a concrete pool hole with no shade and poor ventilation... but our building was rendered above ground with good ventilation. I will however give a few walls "the knock test" next time I am on site. Does anyone else know of problems relating to the adherence of the cement rendering to AAC blocks? Apart from wetting the wall first before applying the plastering mortar there is nothing in the QCON Handbook on the subject.

-

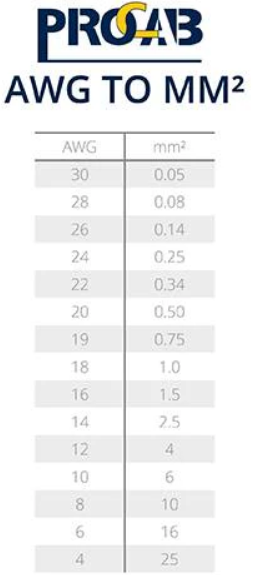

Whilst on the subject of breaker sizing, I have a related question about cable sizing. We are about to start the electrical wiring of our new house build in Isaan. I have read that wire size AWG 18 is good for 10A or current, AWG 14 is good for 15A, AWG 12 is good for 20A, and AWG 10 is good for 30A. The problem is that most Thai electricians use only one sized wire throughout the entire house unless told otherwise. So I am thinking that apart from the circuits for the water heater (6000W therefore 30A wiring required) and the air conditioning units, I could have the rest of our new house wired in AWG 12 (20A) for all the power circuits, and AWG 14 (15A)for the lighting circuits. We have no plans for an electric oven so that is not on our consumers list. Thoughts/comment please?

-

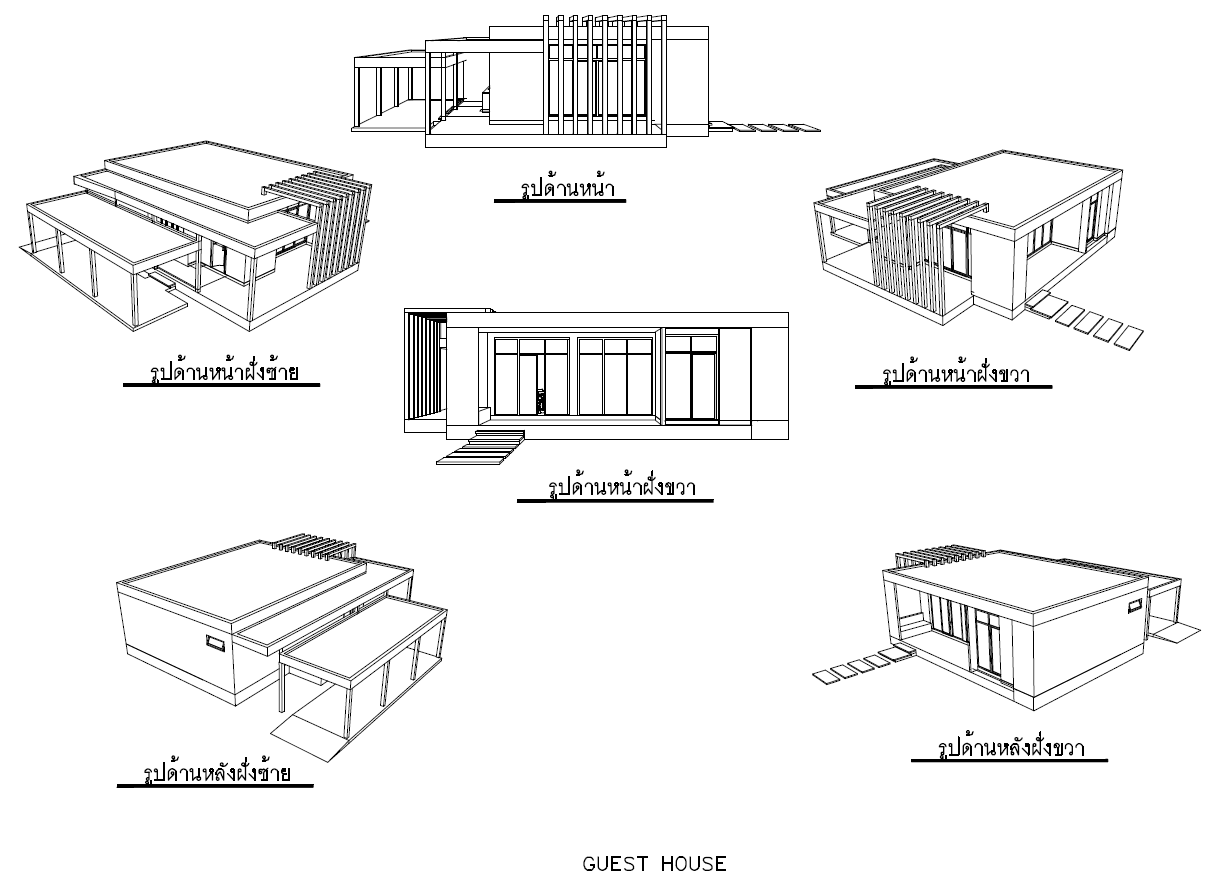

Thank you! Although we have tried to make it "reasonably passive" we also wanted to retain a modern and eye-catching look to the building, as well as providing functionality for practical outdoor living/eating/drinking areas. We will have large areas of glass on the North and East sides of the building, but the double-glazing (as well as suitable curtains) should keep most of the heat out, except in the cool season when a bit of morning warmth from the sun will be most welcome. The only changes we have made to the architect's original plans are 1) a concealed sloping steel roof instead of a flat concrete roof, and 2) a 15° sloping roof on the South facing carport which will provide support for near-future PV solar panels.

-

No to be honest I hadn't even considered that... what did you use for the tapping? Am I likely to hear any difference between tapping a cement rendered AAC block and a cement rendered RC lintel or RC column?

-

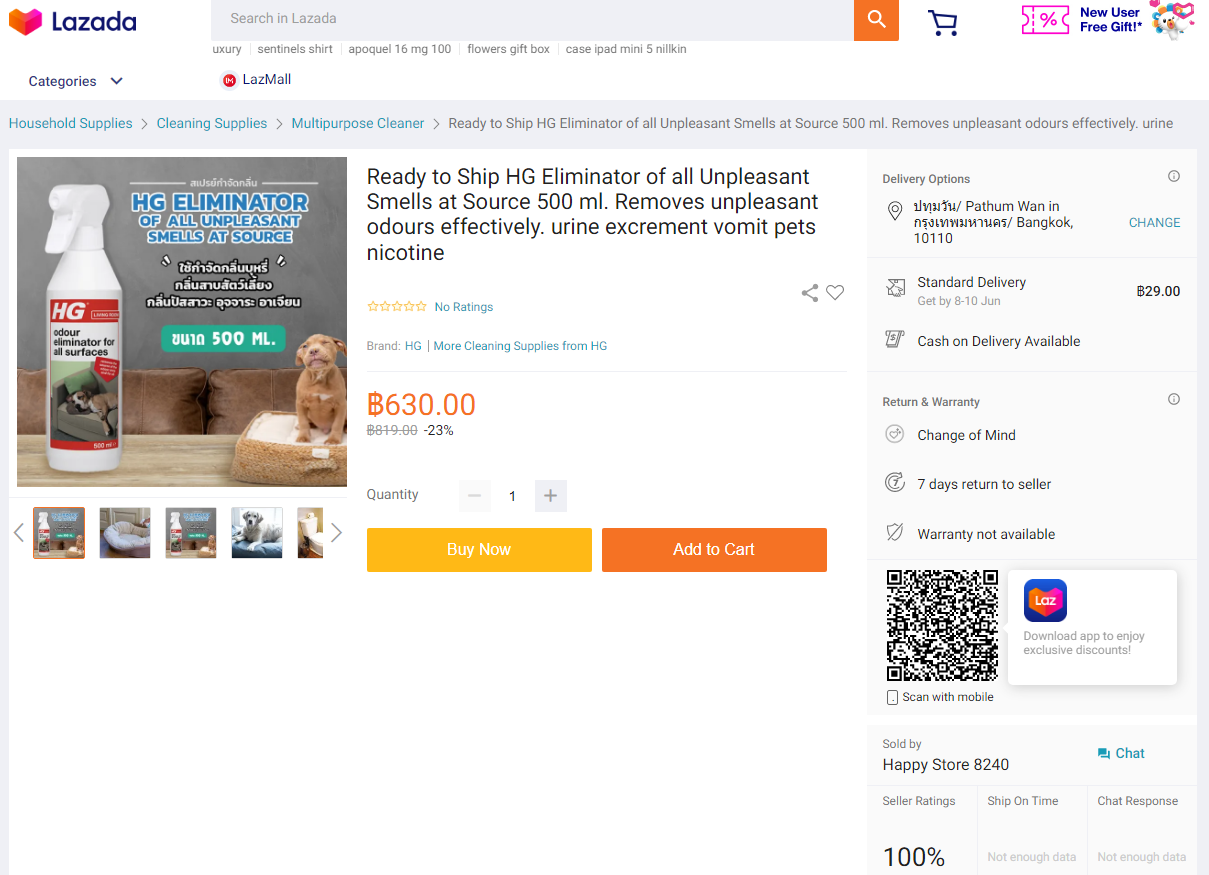

Upholstery odour neutraliser - Any recommendations?

Encid replied to Crossy's topic in Thailand Motor Discussion

-

Thunderstorms hit Thailand: Heavy rainfall sparks flash flood warnings

Encid replied to webfact's topic in Thailand News

Overcast but not a drop of badly needed rain here in Sattahip. -

I have used Netafim 8mm micro drip line systems and they do a great job around our fruit trees. The dripline goes around the trees so gives a really good deep watering way better than any sprinkler IMO because they do clog up. However I'm willing to give these a try... thanks!

-

Not that I know of... In any case my TV does not do the 10-bit HEVC H265 codec translation... the Android box with Kodi or VLC software does.

-

I have never "cleared the cache" on my Hisense TV... do it regularly on the Android box of course but never the TV. I guess you are using the "smart" features of the TV and not like a dumb monitor like I am?

-

All the internal and external cement rendering of the building (except for the bathroom) is now complete, and the next work face is the gutters/roof drainage. The number and size of the drains are being modified from 2" to 4" as agreed with our builder, and will be completed, sealed, and tested for leaks before the roof goes on. The drains will pass through the wall and the rain water will cascade down to the lower roof level, which in turn will be drained into a 12" PVC pipe in the carport which will initially discharge to the West side of the building... away from the retaining wall. All these drains will be concealed by the ceiling(s). Should we get any leaks in the system in the future, the leaks will be on the walls in the rooms on the South side of the building, ie. the bathroom and the internal kitchen. We have no plans for any electrical appliances to be inside the kitchen so if leaks do occur they will not be too much of a problem. If leaks do occur we can always cut the AAC blocks and the concrete gutter and install more 4" drains... but I am hoping that we have over-designed it sufficiently so this will never happen. Future plans of rain water harvesting may be possible and fairly simple to implement, as it would only involve re-routing the 12" PVC pipe... but that is another project and not being considered seriously just now.