-

Posts

10,579 -

Joined

-

Last visited

Content Type

Events

Forums

Downloads

Quizzes

Gallery

Blogs

Everything posted by sometimewoodworker

-

Exterior sunshading - why not common in Thailand?

sometimewoodworker replied to CLW's topic in DIY Forum

Not true. The windows need to be both sealed and have zero humidity in the gas (whatever gas it is) within the unit. The standard gas used is argon as it does provide a little extra benefit, is the third-most abundant gas is more than double the molecular weight of nitrogen, and inert. So it is an excellent candidate for filling IGUs and of necessity will have zero moisture in it. So it is IGUs that are no longer sealed that are likely to be the problem. -

Exterior sunshading - why not common in Thailand?

sometimewoodworker replied to CLW's topic in DIY Forum

Come on, that is luxury 1.5mm corrugated steel walls, and why waste money on glass when you can have traditional wood frames with shutters that allow almost perfect ventilation that allows you to see and hear everything your neighbours are doing. -

Exterior sunshading - why not common in Thailand?

sometimewoodworker replied to CLW's topic in DIY Forum

Cheap Charlie? ???? -

the ideal dual 3-prong socket for a kitchen

sometimewoodworker replied to mahjongguy's topic in The Electrical Forum

Actually no they don’t need to be either reversed or vertical they do have to be separated by enough space to allow for the tails Yes the plugs are available, though probably not with a side entry Schuko plugs come in 2 variations though the overwhelming number of them I with my appliances ARE earthed though probably not with a side entry -

It is often more efficient, all of ours have been mounted high.

-

Exterior sunshading - why not common in Thailand?

sometimewoodworker replied to CLW's topic in DIY Forum

See my building thread on CoolThaiHouse and many posts here. -

Exterior sunshading - why not common in Thailand?

sometimewoodworker replied to CLW's topic in DIY Forum

You clearly haven’t seen well designed houses, our house has a rather significant area of glass, about 62 sqm, certainly a few of them allow some heat for a few hours in the morning however they don’t allow noise in, rather they provide excellent noise reduction along with heat exclusion. -

Exterior sunshading - why not common in Thailand?

sometimewoodworker replied to CLW's topic in DIY Forum

Available on government buildings in Laos -

-

I have both a jigsaw and hole saws. It seems that you haven’t used either much, or at all. Someone who is experienced with using a jigsaw, but no hole saws might possibly choose to use one inverted, overhead, on a scaffolding platform, they may even get correctly sized holes and avoid all supports and produce a good job. This is something I would never consider as a good idea unless there were no other options. TLDR hole saw or replace with vented boards.

-

If you look carefully TCT hole saws are reasonably easy to find.

-

As has been mentioned, though possibly not in sufficient detail. Your soffits will not be plasterboard unless the job was badly botched. Plasterboard will disintegrate, the paper backing will be termite food and the moisture will do fun things to the boards. Plasterboard is not remotely water resistant and soffits get wet. So the wise use a waterproof or at least water resistant board and the cheap easy ones are cement based.

-

-

Together with eye and ear protection

-

I have one (though not the double cutter version) and the comments are from experience. The careful to try is required in a drill press as the potential for grabbing the material is high. The yellow saw is of questionable quality ThaiCarpenter stocks the Makita brand that is definitely good quality. However that kind of saw doesn’t have good chip removal which is why the TCT tipped tools are better, you are almost certainly going to want to cut a cement based board and even a high quality many toothed saw will be trashed quickly. all the tools I have suggested are available, though the set under is better obtained from china

-

These are OK if you only have a few holes though you need a good quality one, though for more than that you need a TCT hole saw like these.

-

Excellent in a drill press, deadly dangerous in a hand drill.

-

Something is amiss in the state of Denmark. Your drawing is not of a staircase but a series of landings. as I mentioned my steps have a tread depth of 360mm (310mm would probably be better). Your suggested 600mm is short for a landing a ridiculously long for a staircase. That you seem to have one “step” at 500mm would be a tripping hazard or poor drafting. lighting under the step noses could be a good idea. You can only achieve that if you intend to use thick slabs, likely stone, as the treads, however the design has a 100mm unsupported section, meaning the tread slabs have to be rather thick to achieve that, I wouldn’t think that the design would work with a low rise and shortening the overhang would probably look similar and allow for a slightly thinner slab while still allowing for lighting You are completely (as am I) outside the chart you quoted. However the chart is, in my personal opinion, just a general guide and isn’t OAP friendly.

-

There seems to be rather a confusion about exactly what is the meaning of “a plastic skin” The majority of painting systems for exterior walls are acrylic, acrylic is a plastic, using an acrylic undercoat is a, possibly the, recommended painting system. I have never heard of anyone describing an acrylic undercoat as a plastic skin and the wording used specifically excludes paint as the plastic skin being referred to.

-

That is likely to be much steeper than mine tread hight 100mm tread depth 360mm rise 1 meter run 3.3 metres you could decrease the tread to about 310mm without much problem I suspect that even my brother who has a very unfortunate condition of his long musculature would have been able to get up their stairs easily for several more years. Regrettably his condition, one of the muscular dystrophies, is progressive and though it won’t kill him is making his life more and more inconvenient.

-

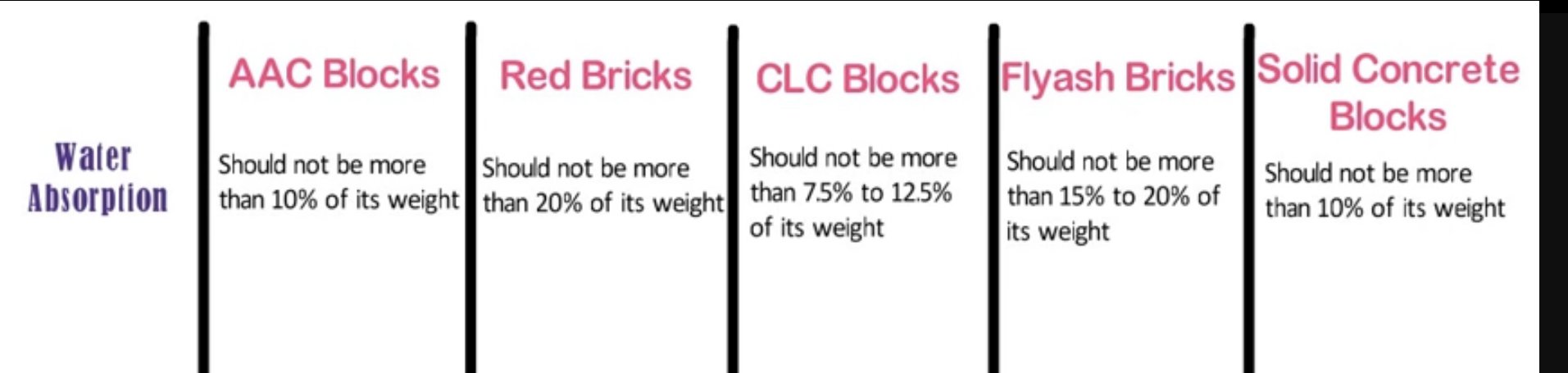

The website is not specifically addressing AAC blocks, they are included, but is also talking about other wall materials So you have material used between blocks/bricks that varies between 3mm and 15mm, so since it’s a site for paint they will recommend a time that is good for any material not for AAC specific walls

-

I used the spacing from one of my Tokyo universities, I’ll get the measurements later today

-

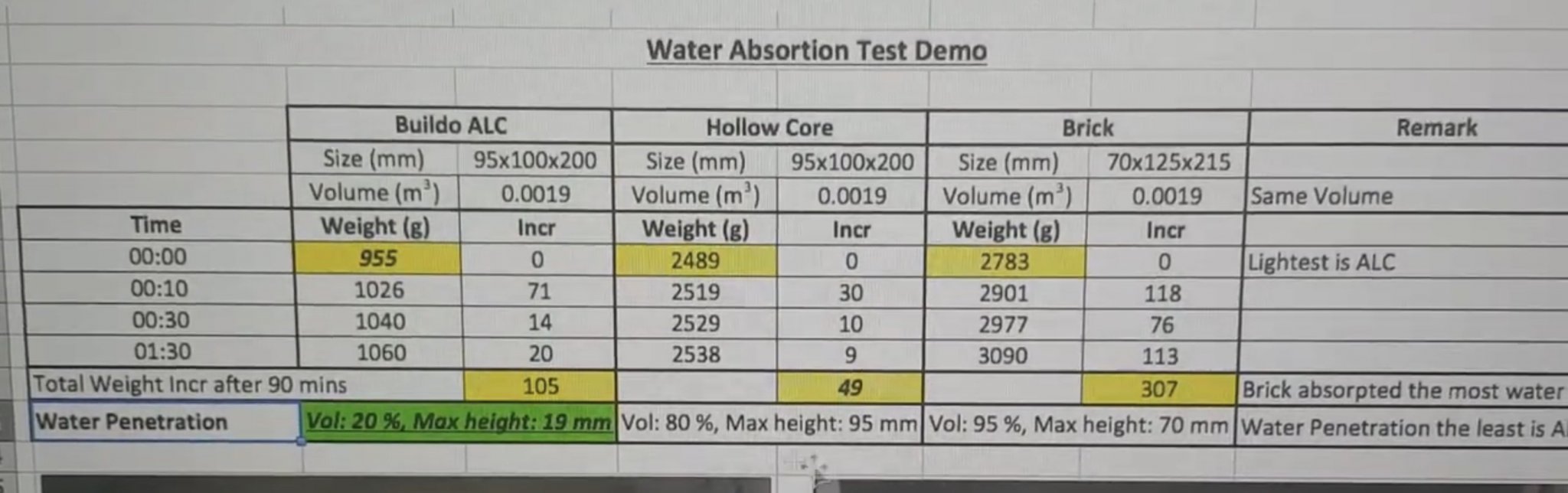

Compared to what??? A block of steel? Of course, a block of expanded polystyrene? Of course. concrete blocks? Absolutely not. Red bricks? Absolutely not. You keep making claims unsupported by the evidence important note. The CLC block you are so enamoured of is heavier than an equivalent AAC block so the volume of water held is naturally greater. and here is a demonstration if the above points. And another, incidentally it includes a drive by illustration of how difficult an AAC block can be to break You conveniently forget to mention that AAC blocks use a glue at about 3mm thickness so the cure time is in hours or possibly a day or two. you also don’t mention the paints formulated to resist alkalinity that are easily available. EDIT the poster who is mostly confused is CLW sorry Encid

-

Don’t forget to incorporate steps designed for those with mobility issues. We have done that (along with a ramp that gets used often) and get frequent compliments from those older folks who visit. You will use about twice the normal length for them. FWIW nobody has ever said anything bad about them.

-

That is absolutely correct. If you have good windows and doors with IGUs you can get some very goo sound reduction